Mechanical Engineering

VISION

To mould socially responsible mechanical engineers and create impact in the society

MISSION

M1- To provide a strong foundation in mechanical engineering through competent faculties and effective teaching methodologies.

M2-Encourage student’s participation in industrial and co-curricular activities that enhances employability skills.

M3- To imbibe students with good leadership qualities and human values through proper mentorship and social outreach.

PROGRAM EDUCATION OBJECTIVES -(PEOs)

PEO 1: Professional competence:Acquire knowledge and skills to solve real life mechanical engineering problems which are competitive and sustainable.

PEO 2: Problem analysis: Occupy in lifelong learning by pursuing certified courses, higher education and engaging in research and development

PEO 3: Leadership quality: Exhibit leadership quality as an individual team player and as managers in the field they choose

PEO 4: Ethics and Social Competence:Work competently and portray ethical values which leads towards solutions in projects which are socially relevant. trends

PROGRAM SPECIFIC OUTCOMES- (PSOs)

PSO1: Technical skills Graduates should gain the knowledge that will help them to solve problems in manufacturing technology and thermal sciences.

PSO2: Graduates must be able to conduct both empirical and analytical analysis of the systems used in machine design and energy engineering

PSO3: Graduates will be able to use the acquired knowledge to solve the problems in the field of industrial engineering and material science.

PSO4: Engineering for Sustainability: Demonstrate ethical reasoning, creative problem-solving, economic analysis, and an understanding of sustainable engineering and the Indian Constitution to successfully tackle engineering and management challenges.

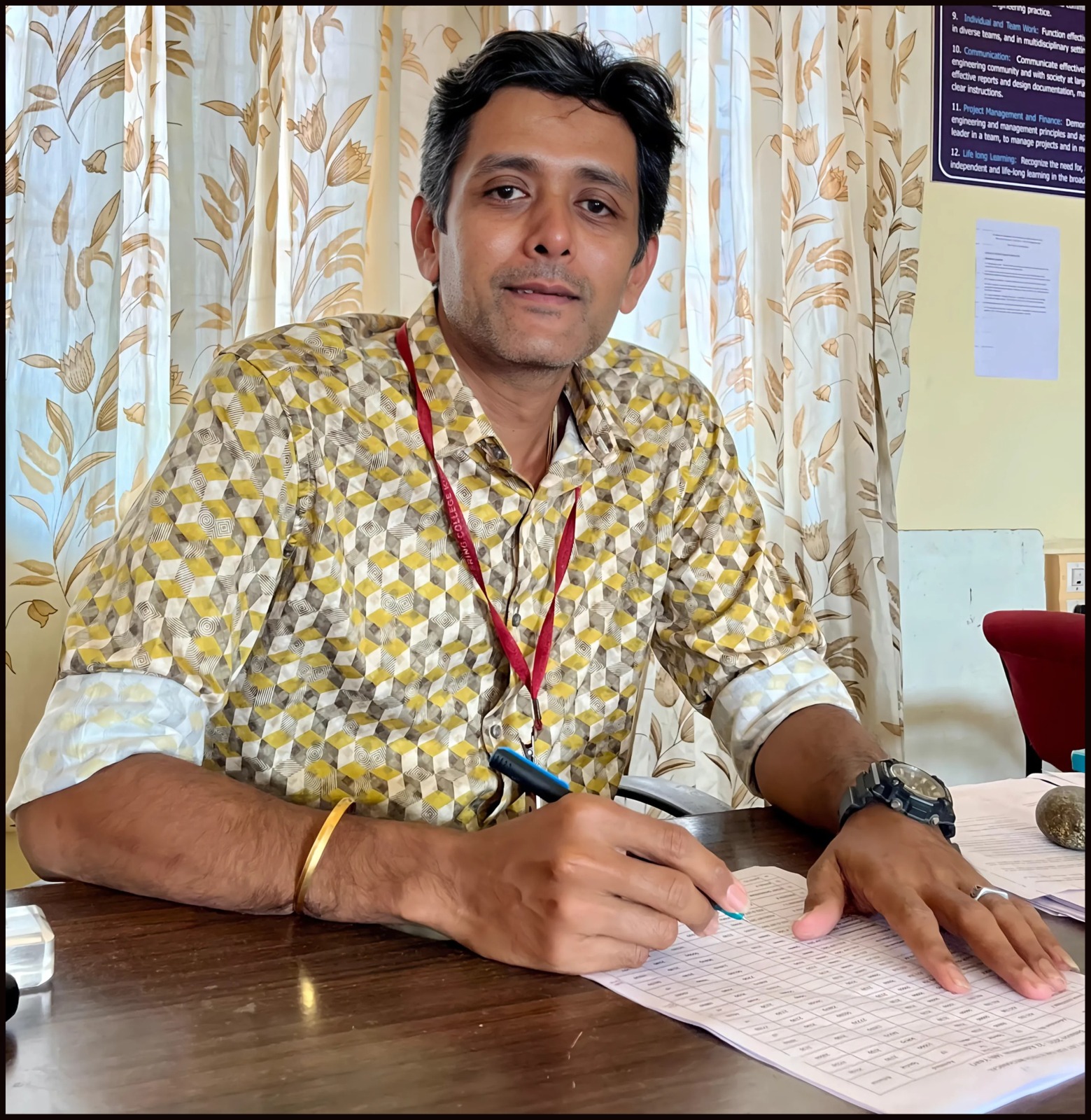

HOD's Message

Dr.Sreeram D

Associate Professor

Head of Department

Established in 2004, the Department of Mechanical Engineering serves as a cornerstone of the institute, renowned for its versatility and excellence. Equipped with state-of-the-art laboratories, the department offers comprehensive hands-on training to undergraduate students, fostering a balance between theoretical knowledge and practical application.

The department is committed to preparing students for specialized expertise in their chosen fields, transforming them into professionals who seamlessly integrate intellectual and real-world experiences to meet societal demands. The academic curriculum and projects are meticulously designed to equip students with a strong foundation in Science, Mathematics, and Engineering, while promoting collaboration, leadership, and technical proficiency in multidisciplinary environments.

A team of highly qualified and experienced faculty members supports this vision, ensuring the holistic development of students into capable engineers and leaders of tomorrow.

My sincere thanks to all the faculty and the students who contribute to the success of the department.

Department level Committee

The roles and responsibilities of PAC are defined as follows.

- Tracking and assessing the attainment of Program Outcomes (POs) and Program Specific Outcomes (PSOs) to ensure continuous improvement.

- Assessing the effectiveness of the program and recommending necessary improvements. Facilitating and monitoring periodic reports on program activities, progress, and status, as well as other special reports for management.

- Encouraging faculty and students to participate in workshops, develop projects and working models, publish research papers, and engage in research activities.

The following committees are formed for attaining the best overall performance of the department in academic, co-curricular and extra-curricular activities:

| Sl No | Name of Committee | Name of Co-ordinator | Role |

|---|---|---|---|

| 1 | Department Academics | Dr. Sreeram D | HEAD |

| 2 | Academic audit and IQAC | Mr. Jibi R | Member |

| 3 | National Board of Accreditation (NBA) | Mr. Jibi R | Member |

| 4 | University Examinations | Dr. Sreeram D | Chief Examiner |

| 5 | Internal Examinations | Mr. Abhiram | Member |

| 6 | Department Library and Resource | Mr. Safeer M | Department in Charge |

| 7 | Department Website | Mr. Jibi R | Department in Charge |

| 8 | Time Table | Mr. Safeer M | Member |

| 9 | Career Guidance and Placement | Mr. Kiran Murali | Member |

| 10 | Institution’s Innovation Council (IIC) | Mr. Arunlal V | Member |

| 11 | Program Assessment and Quality Improvement | Mr. Nikhil KV | Member |

| 12 | Department Discipline | Mr. Arunlal V | Member |

| 13 | Extra-curricular Activities | Mr. Nikhil KV | Member |

| 14 | Games & Sports | Mr. Arunlal V / Mr. Abhiram | Member |

Curriculum and Syllabus

Regulations

| B.Tech Regulation 2019 | Click here |

| B.Tech Regulations 2024 | Click here |

Curriculum and Syllabus

| B.Tech curriculum 2019 APJAKTU | Click here |

| B.Tech curriculum 2024 APJAKTU | Click here |

| B.Tech 2024 first year syllabus group B&C | Click here |

Department Handbook

Professional Bodies

IEEE

The IEEE chapter at AWH Engineering College is a vibrant student-led organization dedicated to fostering innovation, learning, and professional development in the fields of electrical, electronics, and computer engineering. It serves as a platform for students to engage with the latest technologies, enhance their technical skills, and build a network with industry professionals and academic experts.

Through various activities, including workshops, seminars, technical projects, coding challenges, and hackathons, the IEEE AWH chapter strives to keep its members updated with the rapidly evolving technological landscape. Additionally, it provides opportunities for students to collaborate on cutting-edge research and development, while also emphasizing leadership, teamwork, and communication skills.

Being part of the IEEE at AWH College offers members access to global IEEE resources, conferences, and a wide array of professional development opportunities, helping them grow as competent engineers and innovators. Whether you're interested in electronics, programming, robotics, or any other tech-related field, the IEEE chapter at AWH College is the ideal environment to nurture your passion and skills.

International Centre for Free and Open Source Solutions (ICFOSS)

The International Centre for Free and Open Source Solutions (ICFOSS) at AWH Engineering College is a prominent initiative that aims to promote the adoption and development of Free and Open Source Software (FOSS) among students and faculty. As part of the college's commitment to fostering innovation, ICFOSS provides a platform for students to explore, learn, and contribute to the world of open-source technology, equipping them with the skills needed to excel in the rapidly evolving IT landscape.

ICFOSS at AWH Engineering College offers a range of activities, including workshops, seminars, coding competitions, and collaborative projects, all focused on free and open-source technologies. The center also facilitates collaborations with various organizations, industry experts, and open-source communities, allowing students to work on real-world projects and gain hands-on experience.

By actively engaging with FOSS, the center aims to instill in students the importance of software freedom, transparency, and community-driven development. Through these initiatives, ICFOSS at AWH Engineering College nurtures a spirit of innovation, problem-solving, and collaboration, empowering students to create and share solutions that can have a global impact.

Students involved in ICFOSS get the opportunity to learn about various open-source tools, contribute to existing projects, and even start their own open-source initiatives, fostering a deep understanding of the software development lifecycle and collaborative coding practices. This exposure significantly enhances their technical capabilities and prepares them for careers in technology and software development.

IEDC

The Innovation and Entrepreneurship Development Cell (IEDC) at AWH Engineering College is dedicated to fostering a culture of innovation, creativity, and entrepreneurship among students. The IEDC aims to nurture entrepreneurial skills and provide a platform for students to transform their ideas into successful ventures. By organizing workshops, training sessions, and networking events, the cell encourages students to explore the startup ecosystem and equips them with the necessary resources, mentorship, and guidance.

The IEDC at AWH Engineering College also collaborates with industry professionals, alumni, and experts to create opportunities for hands-on learning and real-world exposure. Through various programs and initiatives, the cell plays a vital role in supporting students in turning innovative concepts into viable business solutions, contributing to the development of future entrepreneurs and leaders.

MuLearn

MuLearn is an innovative learning platform designed to empower students and professionals with practical knowledge and skills across a wide range of subjects, especially in the fields of technology, entrepreneurship, and innovation. With a focus on hands-on learning, MuLearn provides interactive courses, workshops, and real-world problem-solving opportunities, enabling users to gain industry-relevant expertise.

The platform emphasizes personalized learning experiences and encourages active participation through collaborative projects and mentorship programs. MuLearn offers resources that bridge the gap between academic knowledge and industry requirements, making it an ideal choice for individuals looking to enhance their skills in a rapidly evolving world. Whether for students aiming to kick-start their entrepreneurial journey or professionals seeking career advancement, MuLearn serves as a valuable tool for continuous learning and growth.

Labs and Facilities

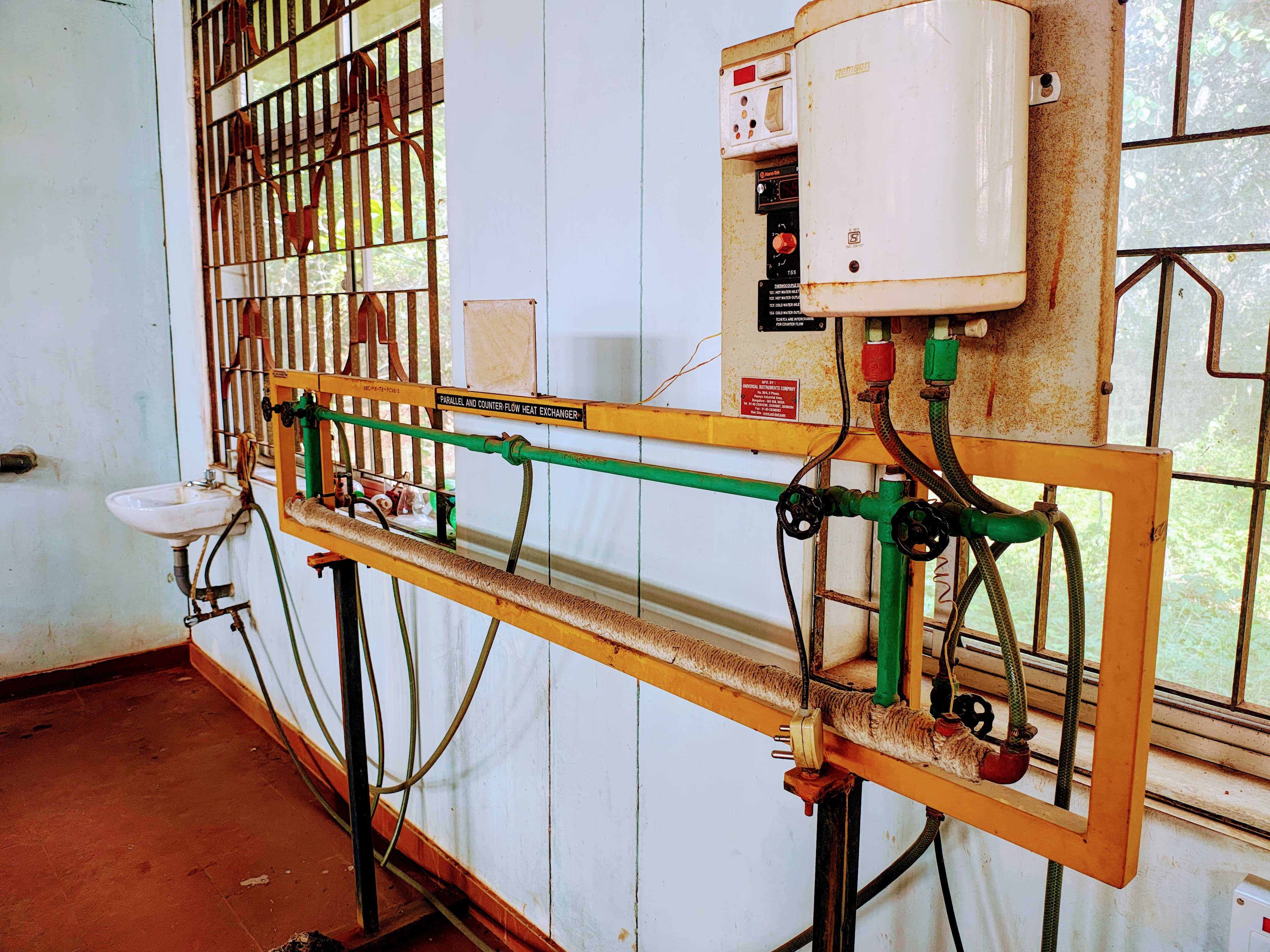

Thermal Engineering Lab

This laboratory provides students with hands-on experience in the fundamental concepts of thermodynamics and heat transfer. Through a variety of experiments, students will gain a practical understanding of:

Thermodynamics: Measurement and analysis of thermodynamic properties, including temperature, pressure, enthalpy, and entropy. Study of thermodynamic processes (isothermal, adiabatic, isobaric, isochoric) and cycles (Carnot, Otto, Diesel). Understanding of the laws of thermodynamics and their applications.

Heat Transfer: Investigation of different modes of heat transfer – conduction, convection, and radiation. Determination of heat transfer coefficients and analysis of heat exchanger performance.

Internal Combustion Engines: Operation and performance characteristics of internal combustion engines (petrol and diesel). Analysis of engine parameters like power, efficiency, and specific fuel consumption.

Refrigeration and Air Conditioning: Study of refrigeration cycles and air conditioning systems. Determination of the coefficient of performance (COP) and analysis of system performance.

Key Apparatus:

The lab is equipped with a diverse range of apparatus, including:

- Bomb Calorimeter: Determination of the calorific value of fuels.

- IC Engine Test Rig (Petrol/Diesel): Measurement of engine performance parameters.

- Refrigeration Test Rig: Determination of the COP of a refrigeration system.

- Air Conditioning Test Rig: Study of the performance of an air conditioning system.

- Heat Exchanger Apparatus (Shell and Tube, Plate): Determination of heat transfer coefficients and effectiveness.

- Thermal Conductivity Apparatus: Measurement of the thermal conductivity of different materials.

- Convection Heat Transfer Apparatus (Natural/Forced): Study of convective heat transfer.

- Thermocouples and Temperature Sensors: Calibration and use for temperature measurement.

- Pressure Gauges and Manometers: Calibration and use for pressure measurement.

Learning Objectives:

- Develop a strong understanding of fundamental thermodynamic principles.

- Gain practical experience in the operation and use of various thermal engineering devices.

- Analyze experimental data and draw meaningful conclusions related to thermodynamic processes and heat transfer.

- Understand the principles of operation of various thermal power plants and refrigeration/air conditioning systems.

- Develop problem-solving skills related to thermal engineering and heat transfer.

- Understand the performance characteristics of internal combustion engines.

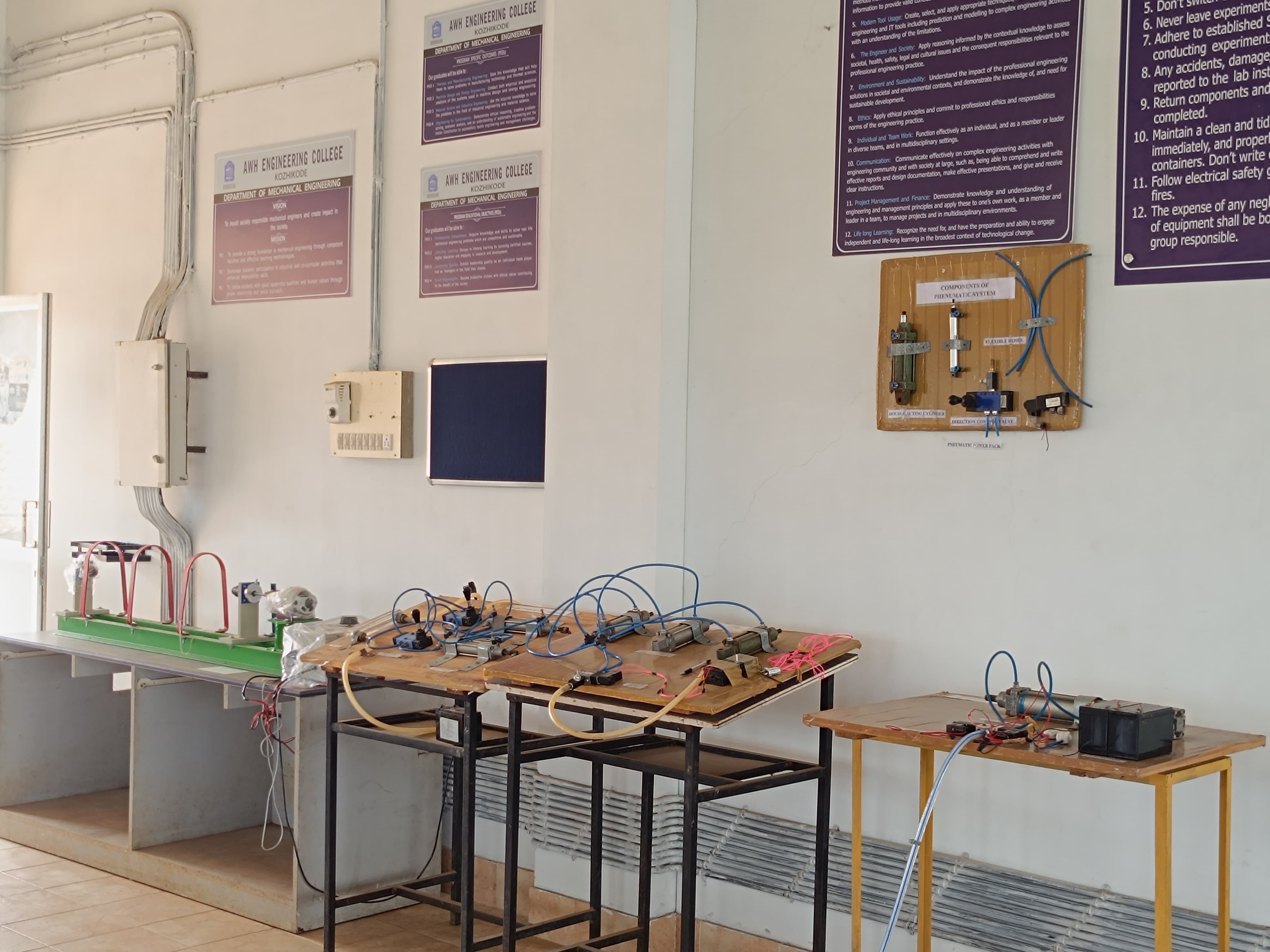

Mechanical Engineering Lab

The Mechanical Engineering Lab is a versatile facility designed to bridge the gap between theory and practice, offering students hands-on experience with real-world applications in mechanics, materials, and manufacturing. It is a crucial part of mechanical engineering education, where students gain practical skills and reinforce their understanding of key concepts.

Key Apparatus:

The lab is equipped with a diverse range of apparatus, including:

- Whirling of Speed of Shaft

- Motorized Gyroscope

- Universal Governor

- DC Servo Motor

- Forced Vibration apparatus

- Liquid Penetrant Test

- 3D Printer

- Water Flow Sensor

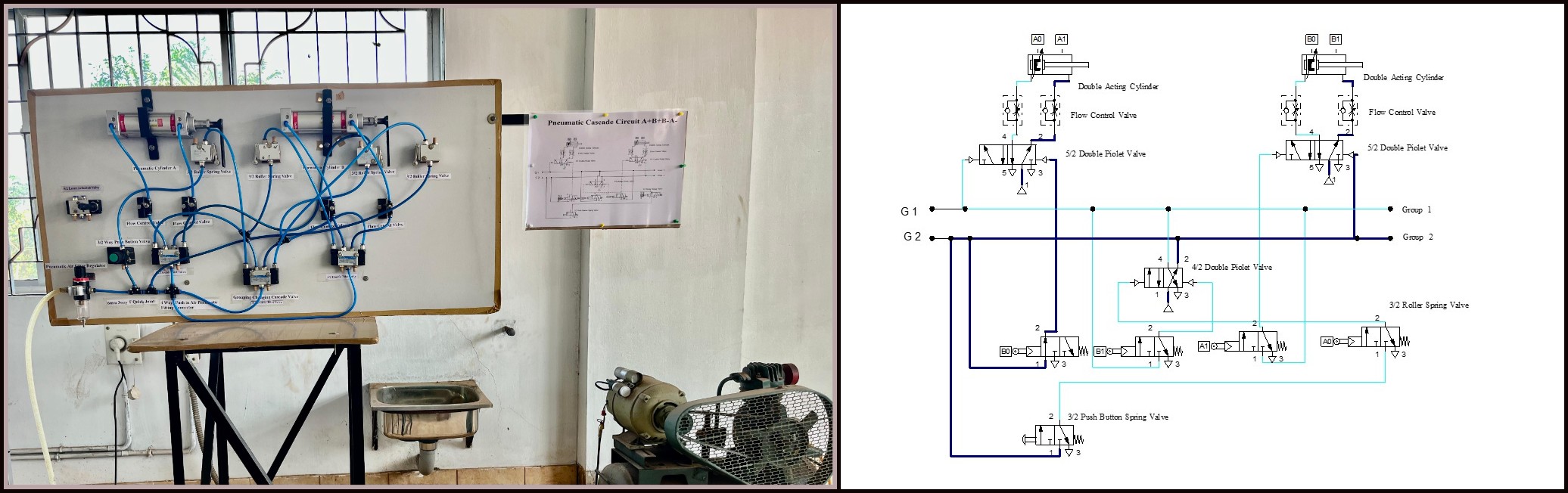

- Hydraulic and Pneumatic trainer kit

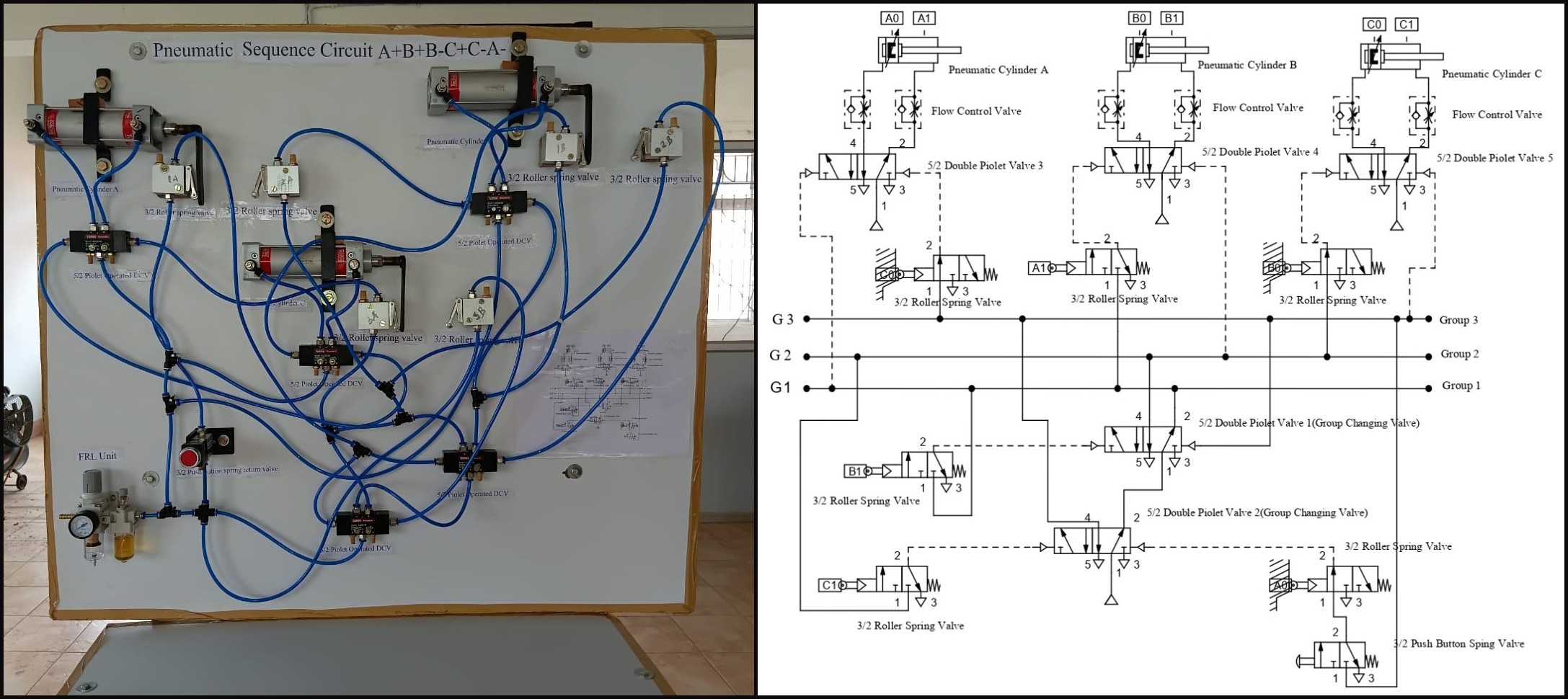

- Pneumatic trainer kit: Sequence circuit A+B+B-A-

Learning Objectives:

- Get practical knowledge on design and analysis of mechanisms in the machines.

- Develop both theoretical knowledge and practical skills in additive manufacturing technologies.

- Apply the basic concepts of hydraulic and pneumatic actuators and their applications in product and processes.

- Applying the Liquid Penetrant Test (LPT) to castings, to detect surface-breaking defects that may compromise the integrity of the component.

- Use appropriate systems for data acquisition and control of product and processes.

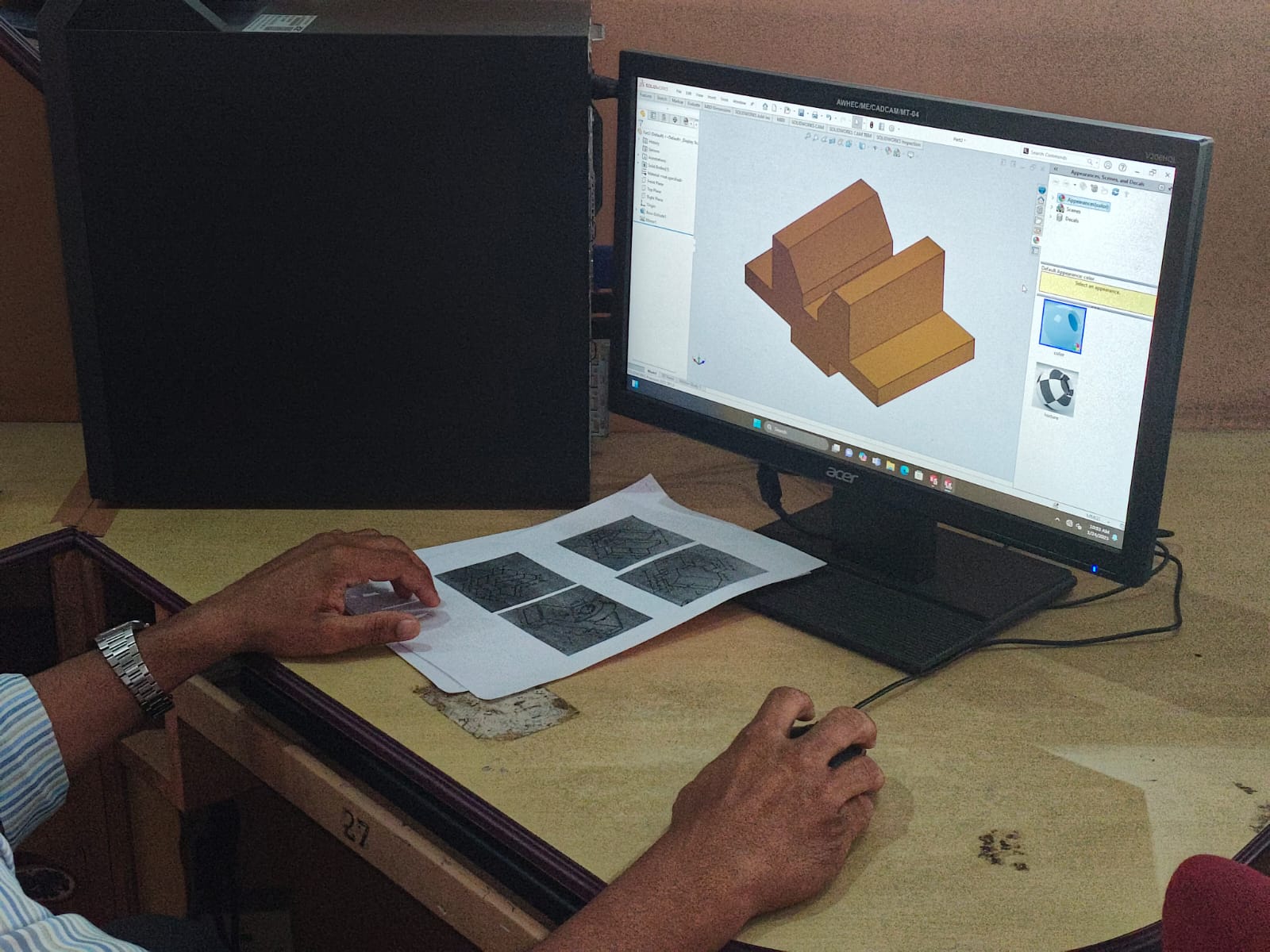

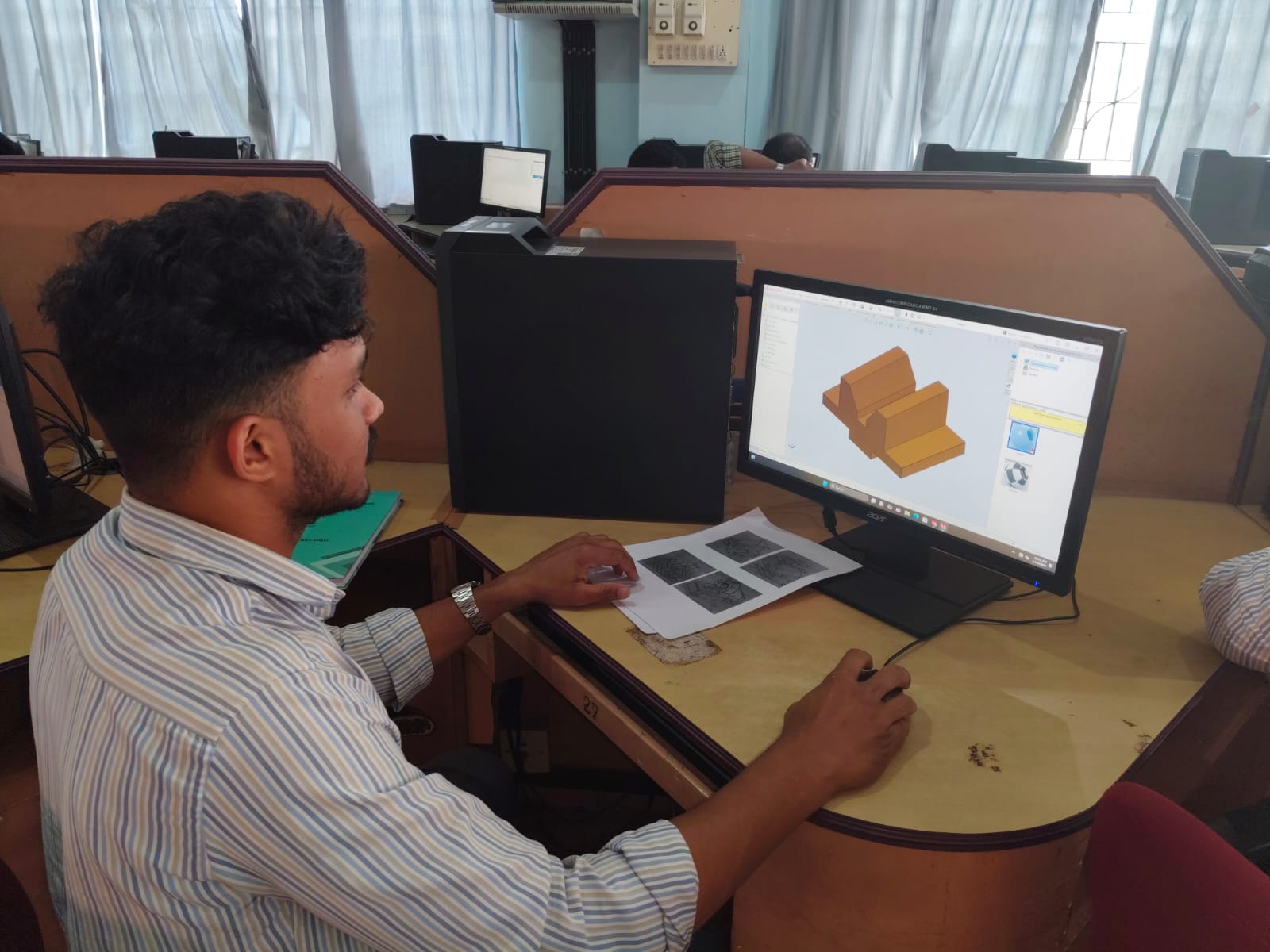

Computer Aided Design and Analysis Lab

The computer-Aided Design (CAD) and Analysis Lab is an essential part of mechanical engineering education, equipping students with cutting-edge tools and software to design, model, and analyze mechanical components and systems. The lab is dedicated to providing hands-on experience with industry-standard software, including AutoCAD, SolidWorks, and ANSYS, to help students understand the design process and perform various simulations.

Software:

SolidWorks

Ansys Mechanical APDL

Ansys Workbench

Key Topics Covered:

Creating 3D assembly models of

Socket and spigot joint

Knuckle Joint

Flange couplings

Plummer block

Screw jack

Tail stock etc

Steady state structural analysis

Steady state thermal analysis

Fluid flow analysis

Learning Objectives:

- Familiarize with different solid modelling and analysis software.

- Introduce students to the basics and standards of engineering design and analysis related to machine components.

- Convey the principles and requirements of modelling and analysis of machine Elements.

- Introduce the preparation of part modelling and assembly modelling of machinery.

- Introduce standard CAD packages to perform Finite Element Analysis of machine Parts.

Fluid Mechanics and Hydraulic Machines Lab

This laboratory provides students with hands-on experience in fundamental concepts of fluid mechanics and hydraulic machines. Through a variety of experiments, students will gain practical understanding of:

- Fluid Properties: Measurement and analysis of fluid properties such as flow rate, pressure, velocity, and viscosity.

- Fluid Statics: Principles of buoyancy, pressure distribution in fluids, and stability of floating bodies.

- Fluid Dynamics: Study of fluid flow phenomena, including Bernoulli's theorem, laminar and turbulent flow, and flow through various orifices and pipes.

- Hydraulic Machines: Operation and performance characteristics of various pumps (centrifugal, reciprocating, gear) and turbines (Pelton, Francis).

Key Apparatus:

The lab is equipped with a diverse range of apparatus, including:

- Mouthpiece Apparatus: To study the effect of different mouthpiece shapes on the discharge coefficient.

- Bernoulli's Theorem Verification: Experimental verification of Bernoulli's equation for fluid flow.

- Venturimeter: Measurement of fluid flow rate using a Venturimeter.

- Orifice Meter: Measurement of fluid flow rate using an Orifice meter.

- Orifice Apparatus: Study of flow through various orifices (sharp-edged, rounded).

- Metacentric Height: Determination of metacentric height of floating bodies.

- Rectangular Notch: Measurement of flow rate using a rectangular notch.

- Triangular Notch: Measurement of flow rate using a triangular notch.

- Reynolds Apparatus: Observation and study of laminar and turbulent flow regimes.

- Major Loss Apparatus: Investigation of head losses due to friction in pipes.

- Minor Loss Apparatus: Study of head losses due to various pipe fittings (elbows, valves).

- Water Meter: Calibration and performance evaluation of water meters.

- Centrifugal Pump: Performance testing and characteristic curves of a centrifugal pump.

- Reciprocating Pump: Performance testing and characteristic curves of a reciprocating pump.

- Gear Pump: Study of the operation and performance of a gear pump.

- Pelton Turbine: Performance testing and characteristic curves of a Pelton turbine.

- Francis Turbine: Performance testing and characteristic curves of a Francis turbine.

- Rotameter: Measurement of fluid flow rate using a Rotameter.

Learning Objectives:

- Develop a strong understanding of fundamental fluid mechanics concepts.

- Gain practical experience in the operation and use of various fluid flow measurement devices.

- Analyze experimental data and draw meaningful conclusions.

- Understand the principles of operation of various hydraulic machines.

- Develop problem-solving skills related to fluid mechanics and hydraulic machinery.

Computer Aided Machine Drawing Lab

This lab provides students with practical experience in computer-aided drafting (CAD) techniques, focusing on machine drawing standards and conventions. Students will learn to create 2D models of various machine components using industry-standard software like Autodesk AutoCAD or SolidWorks.

Key Topics Covered:

- Machine Drawing Conventions:

- Understanding and applying standard conventions for representing various machine elements.

- o Creating sectional views, auxiliary views, and other necessary views for complete representation.

- Limits, Fits, and Tolerances:

- Learning about different types of fits (clearance, interference, transition).

- Applying dimensional tolerances (form, positional) and understanding their significance.

- Understanding and using machining symbols to convey manufacturing instructions.

- Welding Symbols and Representations:

- Learning to read and interpret welding symbols as per the AWS standards.

- Creating weld symbols for different types of welds (groove, fillet, spot, etc.).

- Riveted Joints:

- Studying different types of riveted joints (lap, butt, corner).

- o Creating 2D drawings of riveted joints with proper dimensioning and annotations.

- Surface Roughness:

- Understanding the concept of surface roughness and its importance in engineering.

- Representing surface roughness using standard symbols and specifying roughness values.

- Thread Representations:

- Learning different methods of representing threads (simplified, conventional, and actual).

- Creating drawings of threaded components (bolts, nuts, screws).

- 2D Drawings and Assembly Drawings

- Creating assembly drawings of various machine components such as:

- Knuckle joint

- Gib and cotter joint

- Oldham's coupling

- Flanged coupling

- Screw jack

- Plummer block

- Connecting rod

- Stuffing box

- Creating assembly drawings of various machine components such as:

Learning Objectives:

- Develop strong skills in computer-aided drafting and design.

- Understand and apply engineering drawing standards and conventions.

- Create accurate and detailed 2D and 3D drawings of machine components.

- Develop the ability to interpret and create assembly drawings.

- Gain a strong foundation in machine design principles.

- Prepare students for careers in engineering and manufacturing.

Machine Tools Lab 1

The Machine Tools Lab is designed to provide students with practical experience in operating and understanding various machine tools, along with the theoretical principles behind machining processes.

Key Apparatus:

The lab is equipped with a diverse range of apparatus, including:

- Centre Lathe: For turning, facing, threading, and other machining operations.

- Drilling Machine: For drilling, reaming, and tapping.

- Shaping Machine: For producing flat surfaces, grooves, and other shapes.

- Slotting Machine: For internal and external keyways and slots.

- Grinding Machine: For achieving fine surface finishes and precise dimensions.

- Welding Machine: For joining metals through various welding techniques.

The lab equips students with the skills and knowledge necessary for real-world applications in manufacturing and production engineering.

Learning Objectives:

- Familiarize students with the parts and operations of key machine tools such as lathe, drilling, shaping, milling, slotting, and grinding machines.

- Gain hands-on experience in machining processes and analyze the effects of cutting parameters (feed, velocity, and depth of cut) on cutting force and surface finish.

- Develop foundational knowledge of tool materials, cutting fluids, and tool wear mechanisms.

- Apply mathematical principles to calculate machining parameters for different processes, ensuring efficient and precise machining.

Machine Tools Lab 2

The Machine Tools Lab is designed to provide students with practical experience in operating and understanding various machine tools, along with the theoretical principles behind machining processes.

Key Apparatus:

The lab is equipped with a diverse range of apparatus, including:

- Centre Lathe: For turning, facing, threading, and other machining operations.

- Drilling Machine: For drilling, reaming, and tapping.

- Shaping Machine: For producing flat surfaces, grooves, and other shapes.

- Slotting Machine: For internal and external keyways and slots.

- Grinding Machine: For achieving fine surface finishes and precise dimensions.

- Welding Machine: For joining metals through various welding techniques.

The lab equips students with the skills and knowledge necessary for real-world applications in manufacturing and production engineering.

Learning Objectives:

- Familiarize students with the parts and operations of key machine tools such as lathe, drilling, shaping, milling, slotting, and grinding machines.

- Gain hands-on experience in machining processes and analyze the effects of cutting parameters (feed, velocity, and depth of cut) on cutting force and surface finish.

- Develop foundational knowledge of tool materials, cutting fluids, and tool wear mechanisms.

- Apply mathematical principles to calculate machining parameters for different processes, ensuring efficient and precise machining.

Mechanical Workshop

This workshop provides students with hands-on experience in various fundamental machining, fabrication, and traditional manufacturing processes. Through a series of practical exercises, students will gain a working knowledge of:

Metal Cutting: Understanding and application of various metal cutting processes using tools like lathes, milling machines, drilling machines, shapers, and grinders. This includes learning about cutting parameters, tool selection, and surface finish.

Metal Forming: Practical experience in metal forming operations such as bending, drawing, swaging, and forging. Understanding the principles behind these processes and the properties of formed metals.

Joining Processes: Hands-on training in various joining techniques including welding (arc welding, gas welding), brazing, soldering, and riveting. Students will learn about joint design, filler metals, and process parameters.

Fitting and Assembly: Developing skills in fitting and assembling components using hand tools and precision instruments. This includes learning about tolerances, fits, and surface finishing.

Metrology and Measurement: Understanding and using various measuring instruments like vernier calipers, micrometers, dial gauges, and surface roughness testers. Students will learn about measurement techniques, accuracy, and precision.

Smithy (Blacksmithing): Practical experience in shaping metal using forging techniques. Students will learn to heat metal in a forge and use hammers and anvils to create various shapes. This includes understanding the properties of metals at high temperatures and the principles of hot working.

Foundry (Casting): Introduction to the casting process, including pattern making, mold preparation, melting, and pouring of metal. Students will gain an understanding of different casting methods and the properties of cast metals.

Carpentry: Practical experience in working with wood. Students will learn to use hand tools and woodworking machinery to cut, shape, and join wood. This includes understanding different types of wood, joinery techniques, and wood finishing.

Key Equipment and Tools:

The workshop is equipped with a diverse range of machinery and hand tools, including:

- Lathes: For turning operations.

- Milling Machines: For milling operations.

- Drilling Machines: For drilling holes.

- Shaping Machines: For machining flat surfaces.

- Grinding Machines: For finishing operations.

- Welding Equipment (Arc, Gas): For joining metal parts.

- Brazing and Soldering Equipment: For joining metal parts.

- Forging Equipment (Anvil, Hammer, Forge): For shaping metal by forging.

- Sheet Metal Bending Machine: For bending sheet metal.

- Pattern Making Tools (Wood, Metal): For creating patterns for casting.

- Molding Boxes and Sand: For mold preparation in foundry.

- Furnaces (Crucible Type): For melting metal in foundry.

- Carpentry Tools (Saws, Planes, Chisels, Hammers): For woodworking.

- Woodworking Machines (Circular Saw, Planer, Jointer): For woodworking.

- Hand Tools (Hammers, Chisels, Files, Wrenches): For fitting and assembly.

- Measuring Instruments (Vernier Calipers, Micrometers, Dial Gauges): For precise measurement.

Learning Objectives:

- Develop a strong understanding of fundamental machining, fabrication, and traditional manufacturing processes.

- Gain practical experience in operating various machine tools, hand tools, and foundry/smithy equipment.

- Learn about cutting parameters, tool selection, and process optimization.

- Understand the principles of metal forming, joining processes, casting, smithy, and carpentry.

- Develop skills in fitting and assembling mechanical components.

- Learn about metrology and measurement techniques.

- Develop problem-solving skills related to manufacturing and fabrication.

- Acquire a basic understanding of workshop safety procedures and best practices.

Life Skill -Workshop

The hands-on sessions provided valuable practical experience in fundamental engineering skills essential for real-world applications. These sessions helped bridge the gap between theoretical knowledge and practical execution by allowing direct interaction with tools, materials, and processes.

Experience Gained from Practical Sessions

- Drilling Practice Using Electric Hand Drilling Machines

- Cutting of MS Rod and Flat Using Electric Hand Cutters

- Filing, Finishing, and Smoothening Using Electrically Operated Hand Grinders

- MS Rod Cutting Using Hack Saw by Holding the Work in Bench Vice

- Study and Handling Different Types of Measuring Instruments

- Welding of MS and SS Workpieces

- Pipe Bending Practice (PVC and GI)

- Water Tap Fitting

- Water Tap Rubber Seal Changing Practice

- Union and Valve Connection Practice in Pipes

- Foot Valve Fitting Practice

- Water Pump Seal and Bearing Changing Practice

Learning Objectives:

- The hands-on sessions provided an invaluable learning experience, equipping me with essential engineering skills applicable in both academic and professional settings.

- The exposure to machining, welding, plumbing, and mechanical maintenance has strengthened technical foundation, preparing for future engineering challenges.

Project Lab

The project laboratory provides students with a state-of-the-art environment to gain hands-on experience in mechanical engineering. It enhances both their practical and creative skills, enabling them to excel in modeling, designing, and fabrication. The lab plays a key role in fostering self-learning, critical thinking, and problem-solving abilities. Students are encouraged to develop innovative project proposals and execute their final projects with the support of various specialized laboratories. Domain-specific project work is promoted, ensuring students make the most of the available resources for their learning and research endeavors.

| Sl No | Lab Name | Faculty in Charge | Staff In Charge |

|---|---|---|---|

| 1 | Thermal Engineering Lab | Mr. Arun Lal V | Mr. Anishlal N K |

| 2 | Mechanical Engineering Lab | Mr. Jibi R | Mr. Ranjith AP |

| 3 | Computer Aided Design and Analysis Lab | Mr. Jibi R | Mr. Rajeesh M K |

| 4 | Computer Aided Machine Drawing Lab | Mr. Safeer M | Mr. Rajeesh M K |

| 5 | Fluid Mechanics and Hydraulic Machines Lab | Mr. Kiran Murali/ Mr. Safeer M | Mr. Anil Kumar V M |

| 6 | Machine Tools Lab 1 | Mr. Nikhil K V | Mr. Ranjith AP / Mr. Rajeesh M K |

| 7 | Machine Tools Lab 2 | Mr. Kiran Murali | Mr. Rajeesh M K |

| 8 | Mechanical Workshop | Mr. Abhiram | Mr. Anishlal N K |

| 9 | Life Skill - Workshop | Mr. Jibi R | Mr. Anishlal N K |

Course leaflets

2019 Scheme

| SEMESTER | LEAFLET |

|---|---|

| B.tech Mechanical Engineering S3 | S3 leaflet |

| B.tech Mechanical Engineering S4 | S4 leaflet |

| B.Tech Mechanical Engineering S5 | S5 leaflet |

| B.Tech Mechanical Engineering S6 | S6 leaflet |

| B.Tech Mechanical Engineering S7 | S7 leaflet |

| B.Tech Mechanical Engineering S8 | S8 leaflet |

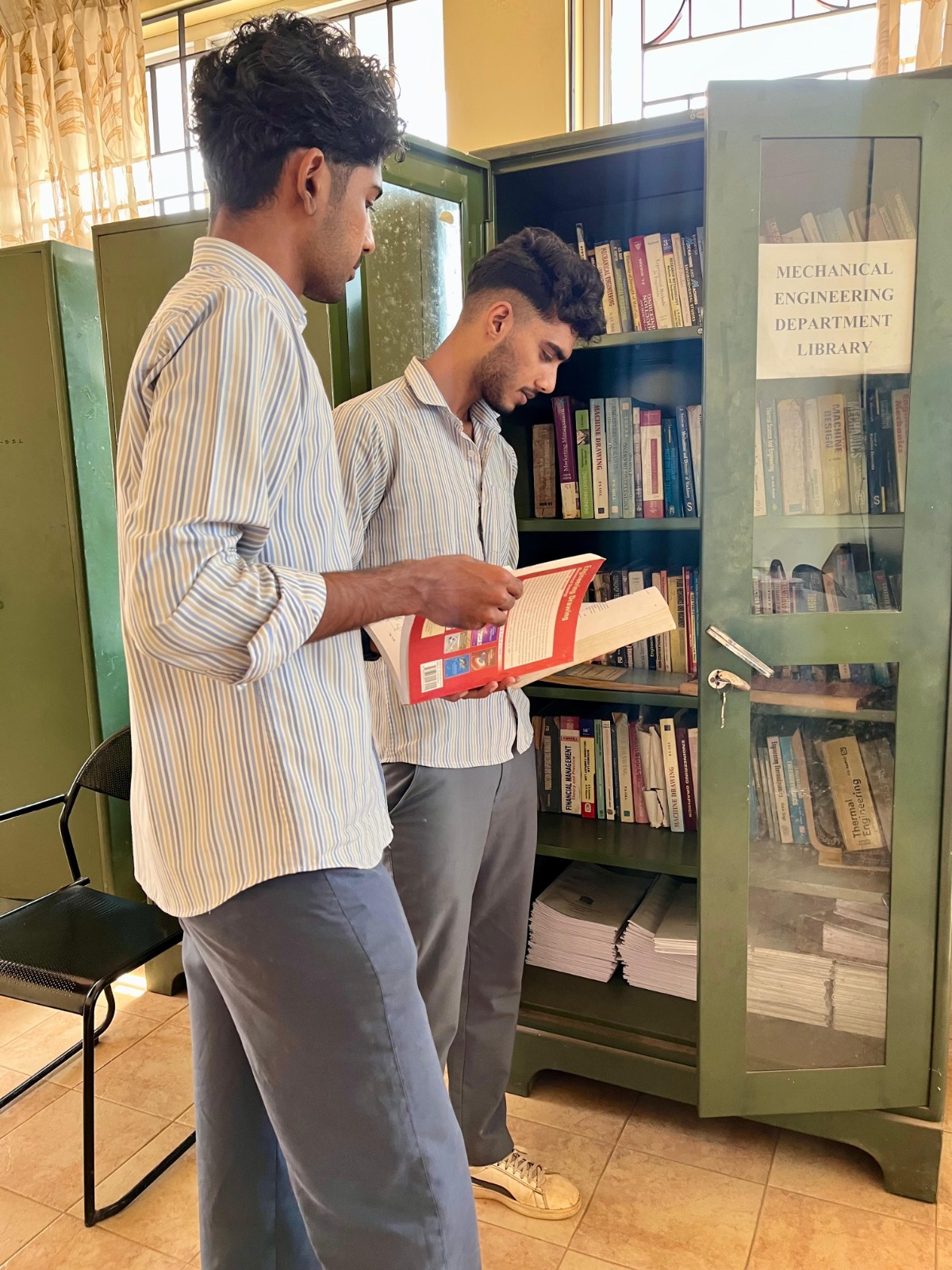

Department Library

The Mechanical Department Library is a valuable resource for students and faculty, offering a diverse collection of materials to support learning and research.

Our Mission:

- Enhance Learning: Provide access to a comprehensive collection of books, journals, project reports, and seminar papers.

- Develop Information Literacy: Equip students and faculty with the skills to effectively locate, evaluate, and utilize information.

- Foster a Supportive Environment: Create a welcoming and inspiring space that encourages intellectual exploration and collaboration.

Our Resources:

The library boasts a growing collection of:

- 200+ Books: Covering a wide range of mechanical engineering subjects.

- 50+ Main Project Reports: Showcasing innovative student projects.

- 200+ Seminar Reports: Exploring diverse topics within the field.

- 15+ Industrial Visit Reports: Offering valuable insights into real-world applications.

Staff in charge

Mr. Safeer M

Assistant Professor

Department Association

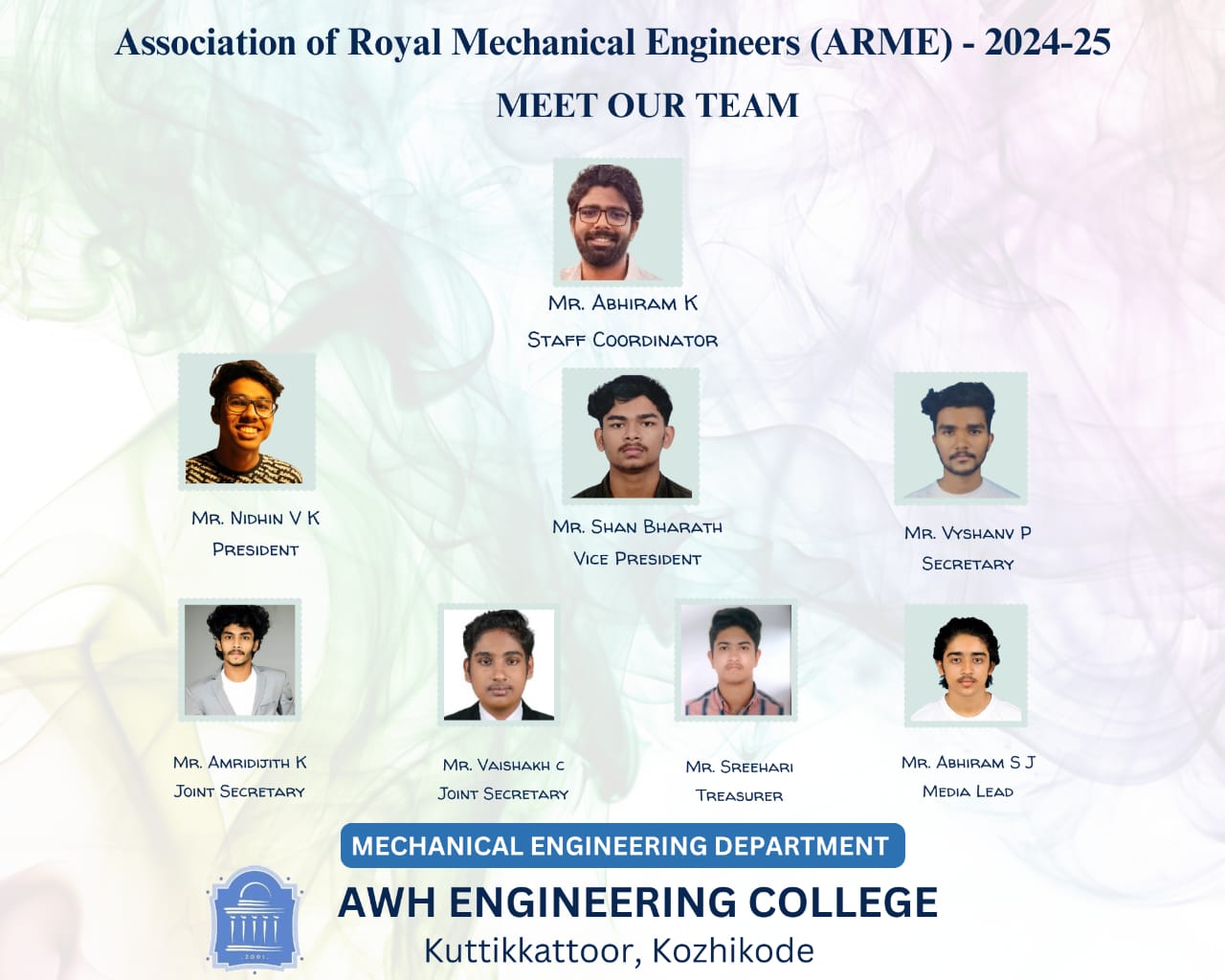

Association of Royal Mechanical Engineers

(ARME)

The Association of Royal Mechanical Engineering (ARME) is a student-driven organization within the Department of Mechanical Engineering. It serves as a platform for students to connect, collaborate, and grow within the field of mechanical engineering. ARME strives to organize events, workshops, and seminars that enhance students academic and professional skills. By fostering teamwork, innovation, and leadership, the association aims to create a vibrant community where students can exchange ideas, gain practical knowledge, and engage in activities that complement their academic journey. It is dedicated to supporting the personal and professional development of its members while creating opportunities for networking and career advancement.

Department Association Overview

The ARME is primarily a student-driven body, supported and guided by faculty members. The association is formed with the goal of enhancing the academic and technical skills of students while promoting creativity, innovation, and collaborative learning.

Objectives

Enhancing Knowledge: Providing a platform for students to boost their technical knowledge and stay updated with the latest advancements in the field of mechanical engineering.

Skill Development: Encouraging students to develop both intra-personal skills (like self-confidence and communication) and inter-personal skills (like teamwork and event management).

Professional Growth: Facilitating interactions with industry leaders and organizing events like workshops, guest lectures, and technical competitions to showcase students' competencies.

Leadership and Teamwork: Promoting leadership qualities and teamwork through various co-curricular and extracurricular activities.

Community Engagement: Encouraging students to participate in social and cultural activities, fostering a sense of responsibility towards society.

Networking Opportunities: Providing a platform for students to connect with peers, alumni, and professionals in the field.

Innovation and Creativity: Organizing events that promote creative thinking, problem-solving, and innovation among students.

Highlights of Activities: Workshops on CAD/CAM software: Hands-on training on industry-standard software like SolidWorks, AutoCAD, and ANSYS.

Technical competitions: Organizing events like design competitions, robotics competitions, and technical paper presentations.

Industry visits: Organizing visits to manufacturing plants and research facilities to provide students with real-world exposure.

Guest lectures: Inviting industry professionals to share their expertise and experiences with students. Technical seminars and conferences: Providing a platform for students to present their research work and learn from other students and researchers.

These initiatives have been instrumental in equipping students with industry-relevant knowledge and skills to fill curriculum gaps in Teaching Learning Process

Staff in charge

Mr. Abhiram K

Assistant Professor

AY 2025-26

NTTF, in association with ARME, organized a micro workshop titled “FORGE AHEAD: Strategic Insights for Tomorrow’s Leaders” on 7th January 2026. The workshop provided valuable insights for aspiring engineering leaders, focusing on current industry expectations and emerging career pathways.

The Association of Royal Mechanical Engineering (ARME) extends its heartfelt appreciation to the 2025 pass-out batch students for attending the convocation ceremony. We wish them great success in all their future endeavours.

" />

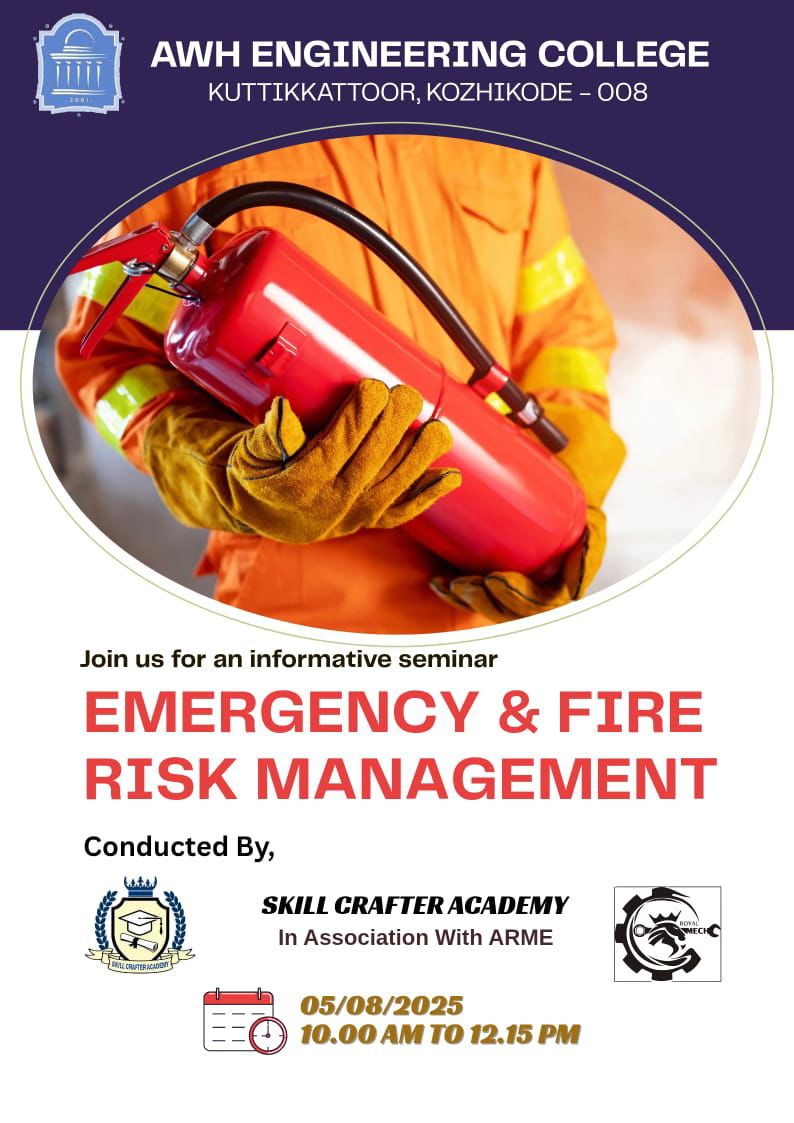

" />Skill Crafter Academy, in association with ARME, organized an informative seminar on Emergency and Fire Risk Management on 5th August 2025.As part of the seminar, a quiz programme on Industrial Hazards and Risk was conducted. Mr. Shan Bharat A K, fourth-year Mechanical Engineering student, secured First Prize. Mr. Navaneeth P and Mr. Minnah KM, pre-final year students, won the Second and Third Prizes respectively. The event aimed to enhance awareness and preparedness among students regarding industrial safety and risk management practices

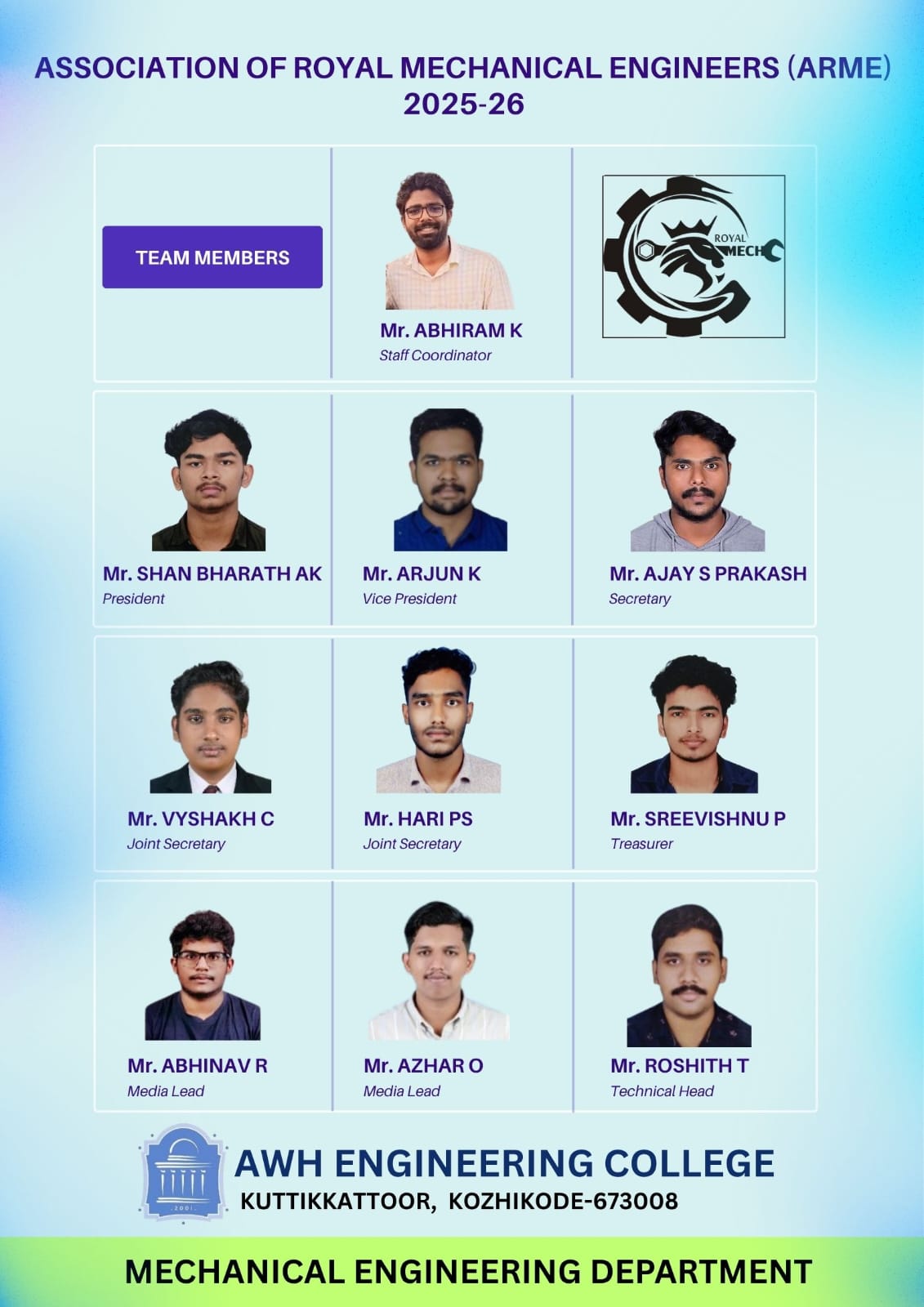

ASSOCIATION MEMBERS 2025-2026

|

Serial No. |

Position |

Name |

Batch |

|

1 |

Staff Coordinator |

Mr. Abhiram K |

|

|

2 |

President |

Mr. Shan Bharath AK |

4th year B.Tech ME |

|

3 |

Vice President |

Mr.Arjun K |

3rd year B. Tech ME |

|

4 |

Secretary |

Mr. Ajay S Praksh |

3rd year B. Tech ME |

|

5 |

Joint Secretary |

Mr. Vyshakh C |

4th year B. Tech ME |

|

6 |

Joint Secretary |

Mr. Hari P |

3rd year B. Tech ME |

|

7 |

Treasurer |

Mr. Sreevishnu P |

4th year B. Tech ME |

|

8 |

Media Lead |

Mr. Abhinav R |

4th year B. Tech ME |

|

9 |

Media Lead |

Mr. Azhar O |

3rd year B. Tech ME |

|

10 |

Technical head |

Mr.Roshith T |

4rd year B. Tech ME |

AY 2024-25

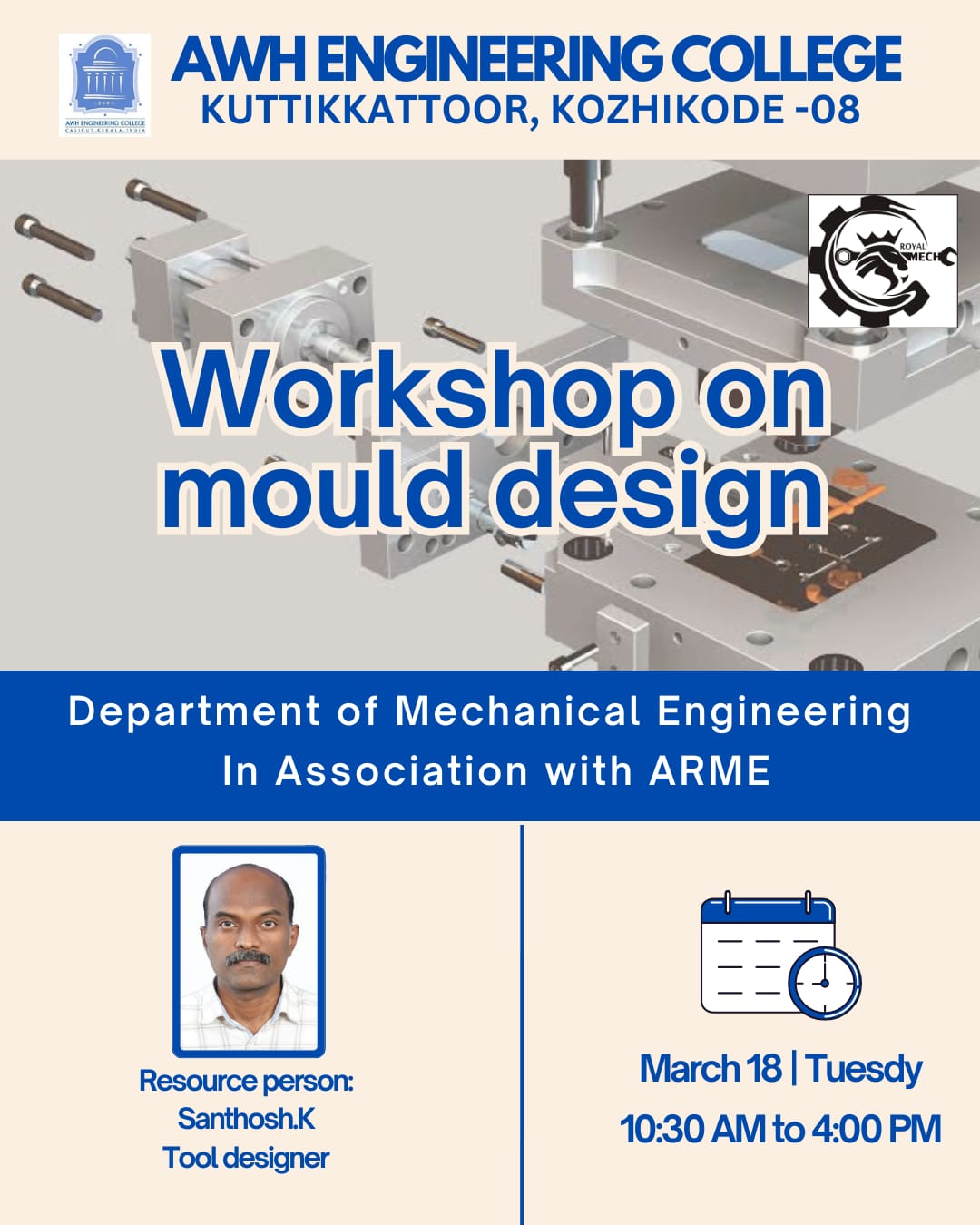

The Department of Mechanical Engineering, in association with ARME, conducted a one-day workshop on Mold Design using SolidWorks Software on March 18, 2025. The workshop provided valuable knowledge in mold design, equipping participants with practical insights into the design and manufacturing aspects of molds using industry-standard software.

Heartfelt Congratulations to the Staff Cricket Team!

The Association of Royal Mechanical Engineers proudly congratulates the Staff Cricket Team for their remarkable victory in the CAPE CUP All Kerala Teachers Cricket Tournament 2025, organized by the College of Engineering Trikaripur. Your dedication, teamwork, and sportsmanship have brought pride to our institution.Wishing you continued success in future tournaments!

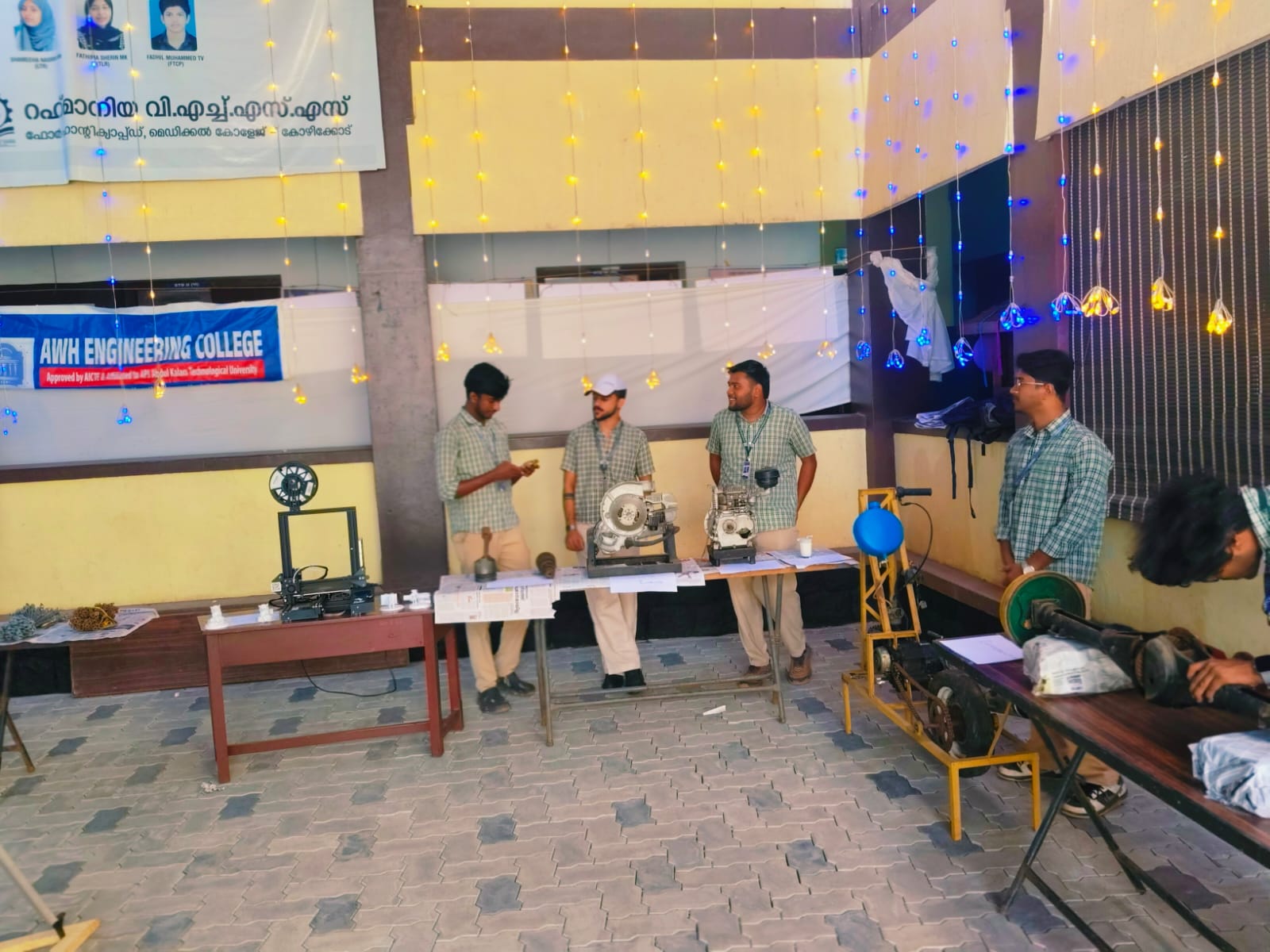

Association of Royal Mechanical Engineering (ARME) participated in an exhibition at Rahmania School Calicut from January 28 to 30 2025.

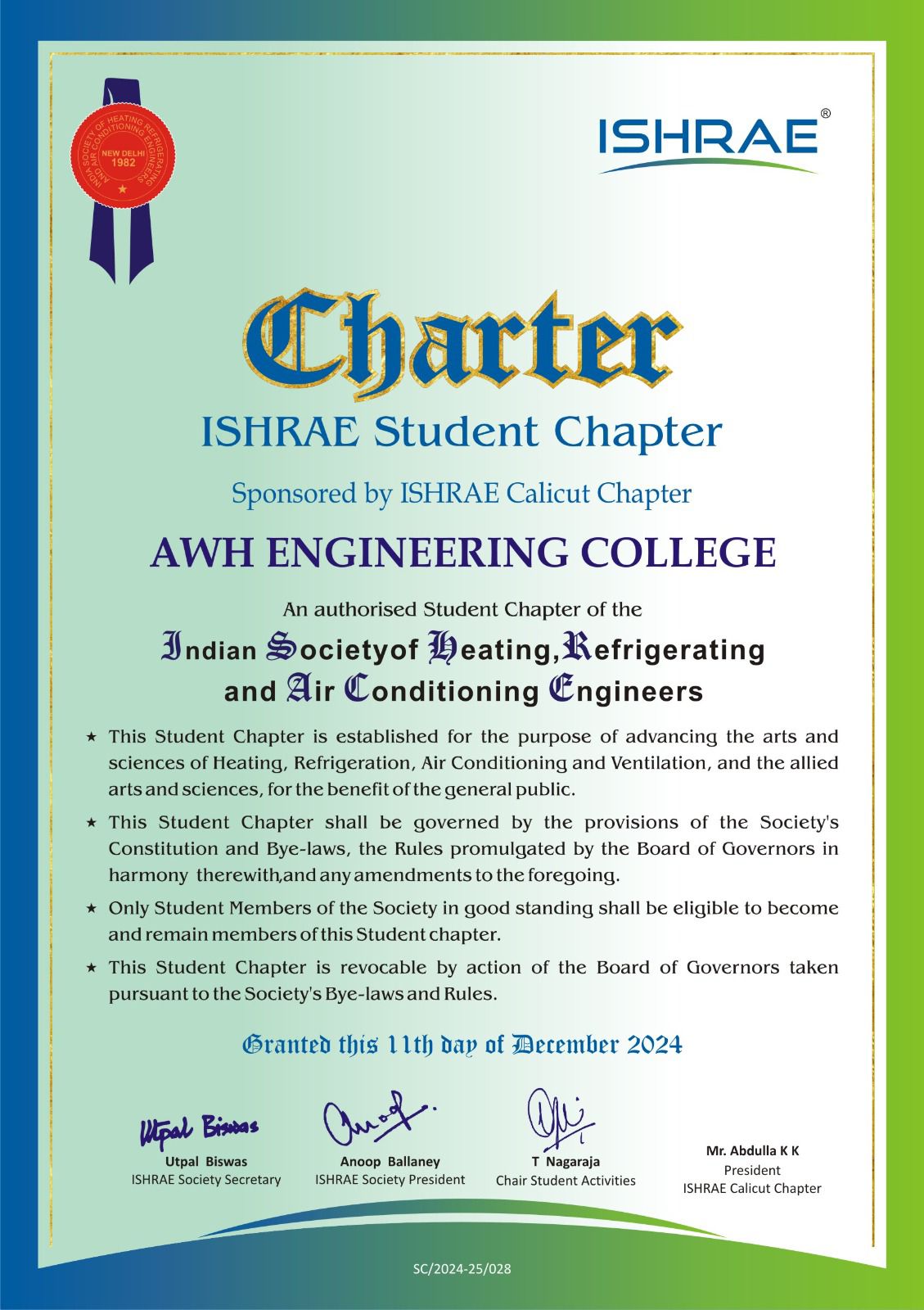

The ISHRAE Student Chapter, an authorized chapter of the Indian Society of Heating, Refrigerating, and Air Conditioning Engineers, was inaugurated at AWH Engineering College on December 11, 2024. This chapter is established to advance the art and science of heating, refrigeration, air conditioning, and ventilation.

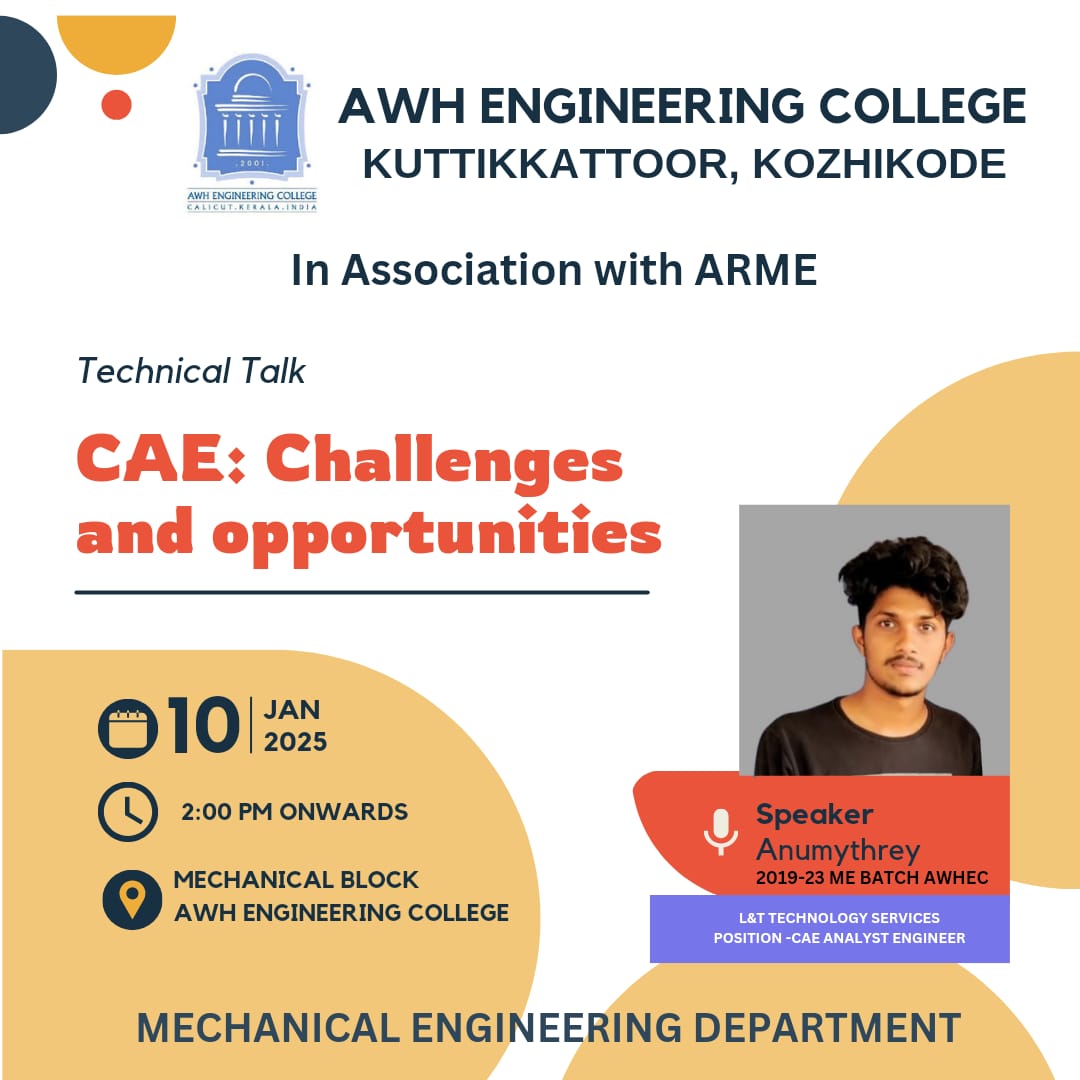

Mr. Anumythery, CAE Analyst Engineer at L&T Technology Services, conducted an expert talk titled 'CAE: Challenges and Opportunities' on January 10, 2025. The event was organized in association with ARME.

The Association of Royal Mechanical Engineering (ARME) extends its heartfelt appreciation to the 2024 pass-out batch students who attended the convocation ceremony. Wishing them great success in their future endeavors.

The collaboration between the Mechanical Engineering Department, ARME, and ISHRAE demonstrating the value of bringing together academia and industry expertise. The event provided students with a valuable platform to learn about the latest trends in the HVAC&R field. Orientation and Technical Talk Oct 9 2024 11 am.

Mr. Arunlal V, Assistant Professor and Ex-Marine Engineer (NYK LINE), conducted an expert talk titled “Seas of Opportunity: Exploring Merchant Navy Careers”on October 7, 2024. The event was organized in association with ARME.

ASSOCIATION MEMBERS 2024-2025

| Serial No. | Position | Name | Batch |

|---|---|---|---|

| 1 | Staff Coordinator | Mr. Abhiram K | |

| 2 | President | Mr. Nidhin V K | 4th year B.Tech ME |

| 3 | Vice President | Mr. Shan Bharath | 3rd year B.Tech ME |

| 4 | Secretary | Mr. Vyshanv P | 4th year B.Tech ME |

| 5 | Joint Secretary | Mr. Amridijith K | 4th year B.Tech ME |

| 6 | Joint Secretary | Mr. Vysak | 3rd year B.Tech ME |

| 7 | Treasurer | Mr. Sreehari | 4th year B.Tech ME |

| 8 | Media Lead | Mr. Abhiram S J | 4th year B.Tech ME |

| 9 | Media Lead | Mr. Sreevishnu | 3rd year B.Tech ME |

| 10 | Technical Head | Mr. Roshith | 3rd year B.Tech ME |

| 11 | Technical Head | Mr. Abhinav P | 2nd year B.Tech ME |

AY 2023-24

The Association of Royal Mechanical Engineers successfully conducted the “BURNOUT” Auto Expo and the Indian Army Weapon and Vehicle Expo as part of ATHMA 2024 in May 2.

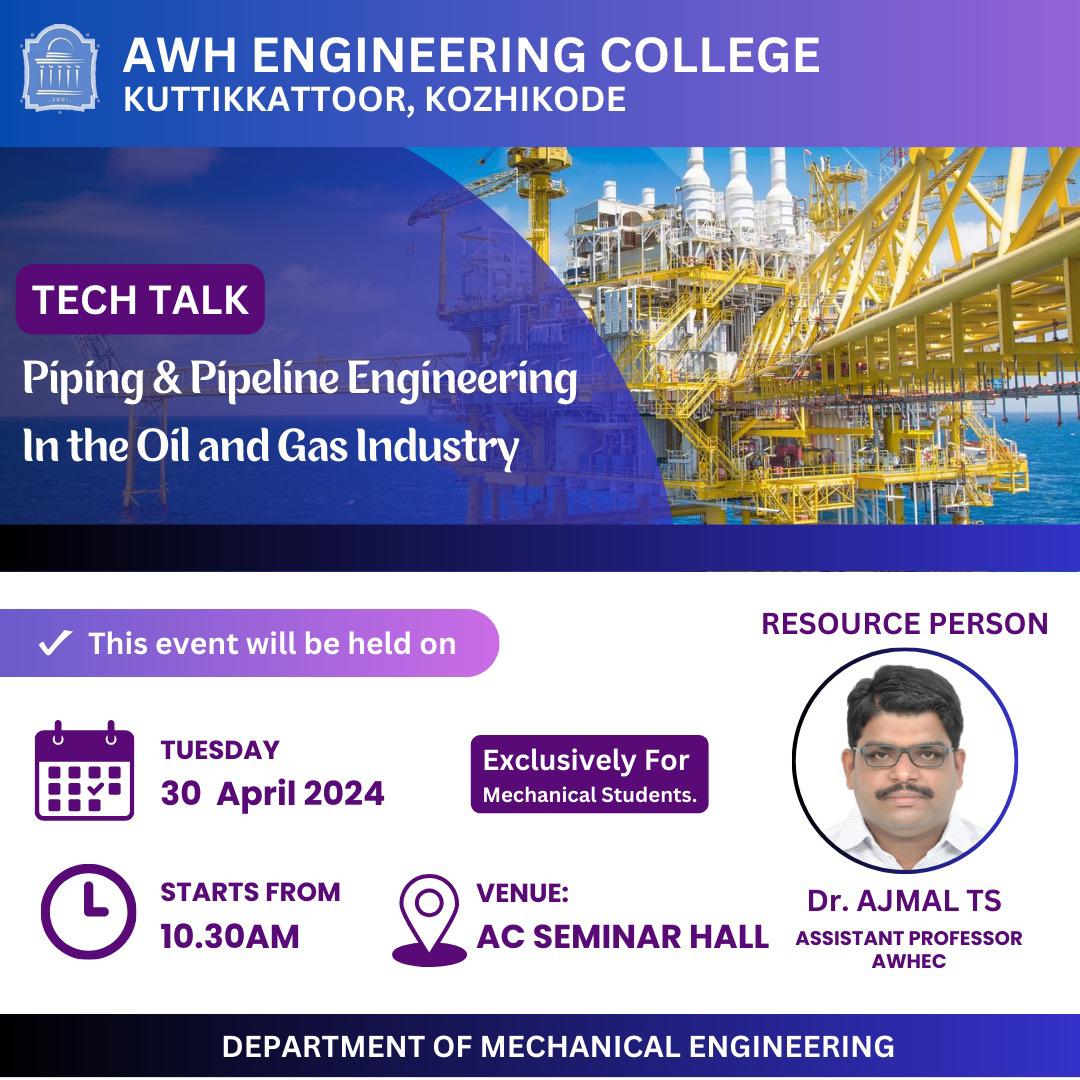

Dr. Ajmal T S conducted a Tech Talk on Piping and Pipeline Engineering in the Oil and Gas Industry on Tuesday, 30th April 2024, as part of Techfest ATHMA 2024.

The Association of Royal Mechanical Engineering (ARME) extends its heartfelt appreciation to the 2023 pass-out batch students who attended the convocation ceremony. Wishing them great success in their future endeavors.

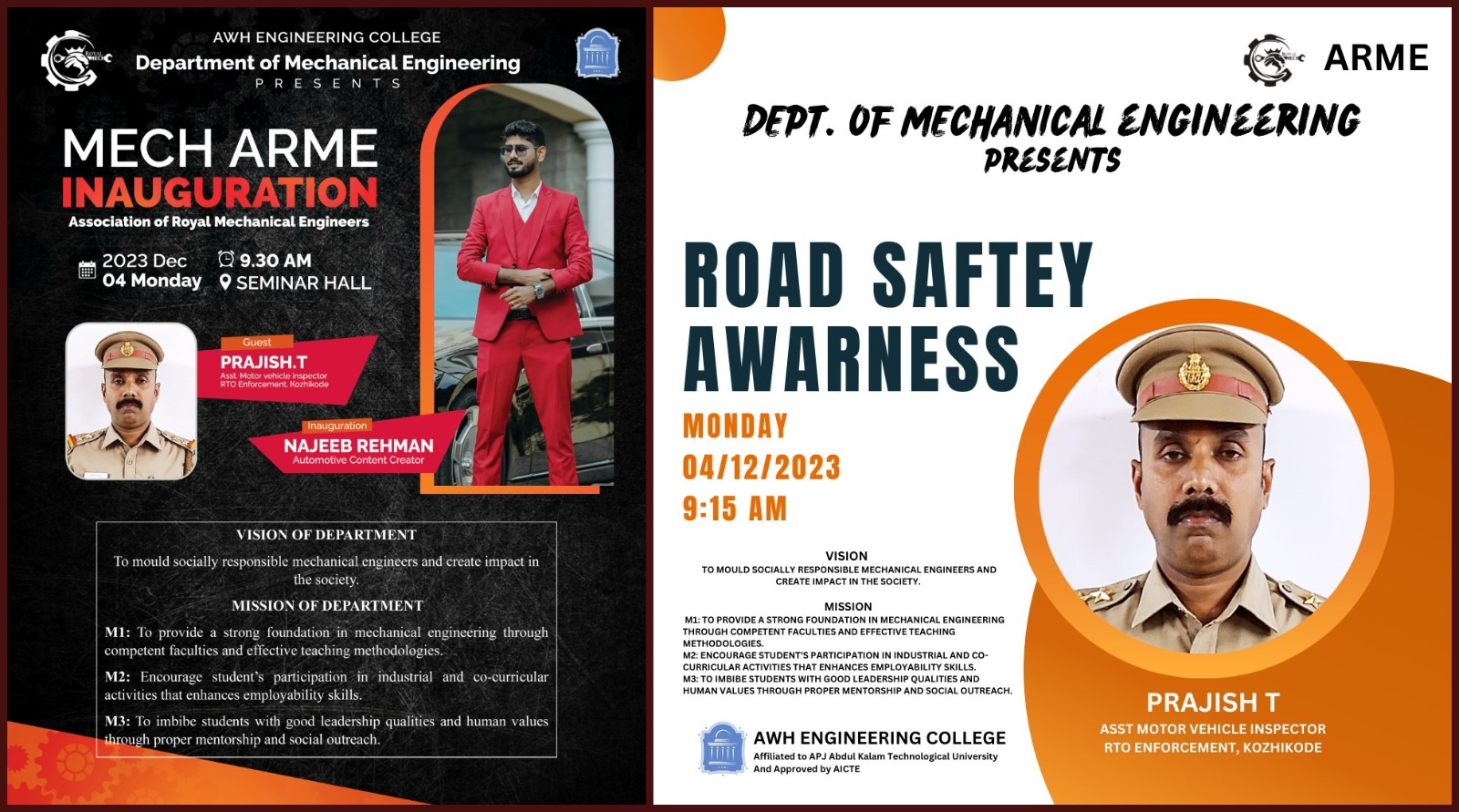

The inauguration of the Association of Royal Mechanical Engineers was held on 4th December 2023. The event was inaugurated by Mr. Najeeb Rehman, an esteemed automotive content creator, in the presence of the chief guest, Mr. Prajesh T, Assistant Motor Vehicle Inspector, RTO Enforcement, Kozhikode.

ASSOCIATION MEMBERS 2023-2024

| Serial No. | Position | Name | Batch |

|---|---|---|---|

| 1 | Staff Coordinator | Mr. Abhiram K | |

| 2 | President | Mr. Shaham Ahammed K | 4th year B.Tech ME |

| 3 | Vice President | Mr. Anujith K | 3rd year B.Tech ME |

| 4 | Secretary | Mr. Vyshanv P | 3rd year B.Tech ME |

| 5 | Joint Secretary | Mr. Ahammed Adil P | 4th year B.Tech ME |

| 6 | Joint Secretary | Mr. Amridijith K | 3rd year B.Tech ME |

| 7 | Treasurer | Mr. Sathar Khalid M C | 4th year B.Tech ME |

| 8 | Media Lead | Mr. Adwaith A | 4th year B.Tech ME |

| 9 | Media Lead | Mr. Abhiram S J | 3rd year B.Tech ME |

| 10 | Technical Head | Mr. Nidhin V K | 3rd year B.Tech ME |

| 11 | Technical Head | Mr. Roshith | 2nd year B.Tech ME |

Association of Royal Mechanical Engineers appreciated the Staff Cricket Team for their remarkable victory in the All Kerala Teachers Floodlight Cricket Tournament, organized by the College of Engineering Thalassery.

Achievements

AY 2025-2026

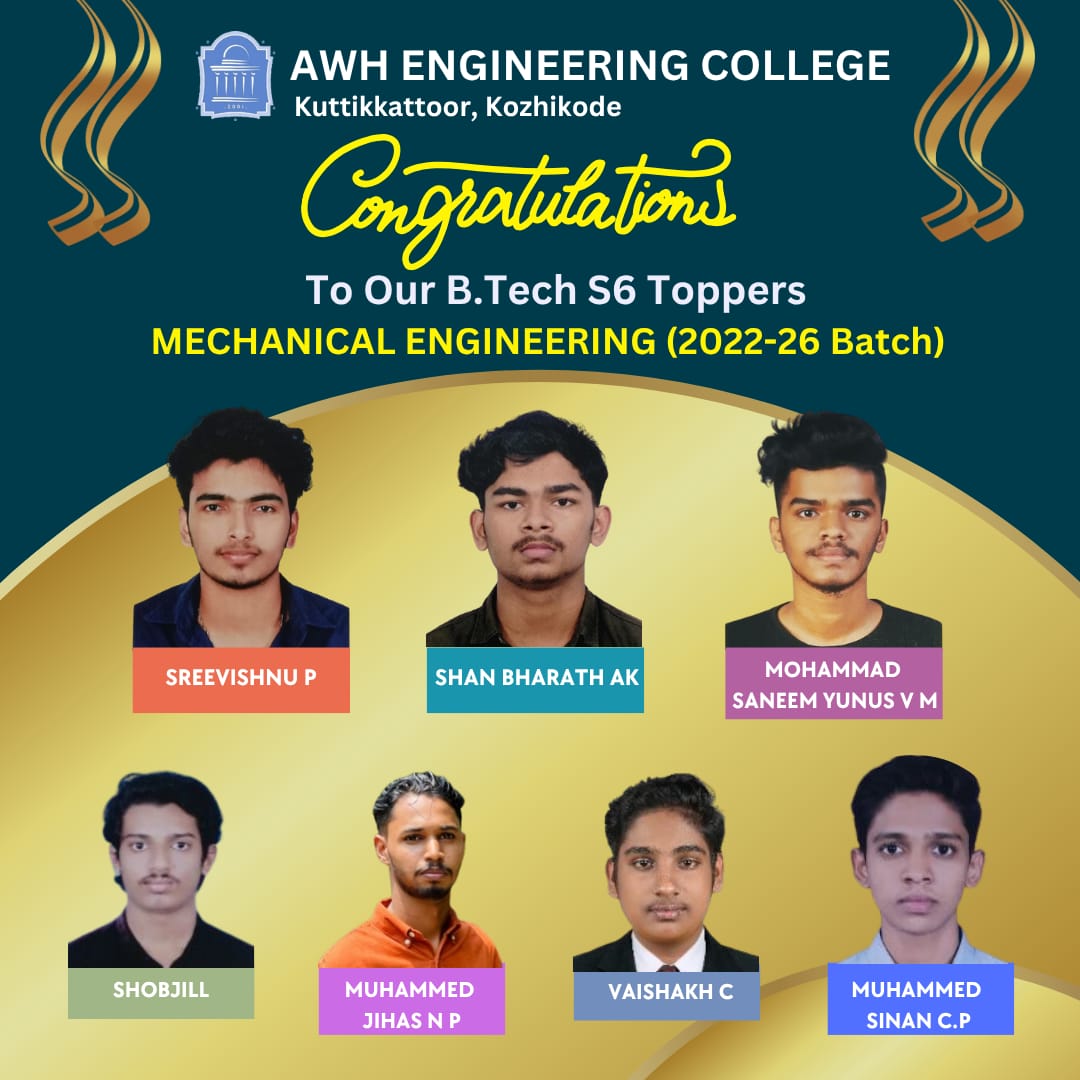

The Mechanical Engineering Department congratulates the B.Tech S6 toppers of the 2022-2026 batch on their outstanding academic achievement.

The Mechanical Engineering Department congratulates the B.Tech S4 toppers of the 2022-2026 batch on their outstanding academic achievement.

Department of Mechanical Engineering Heartfelt Congratulations to Mr. Nidhin V K (2021–2025 Batch) on being placed as a Management Trainee at Fruition Natural Extracts Pvt. Ltd.

AY 2024-2025

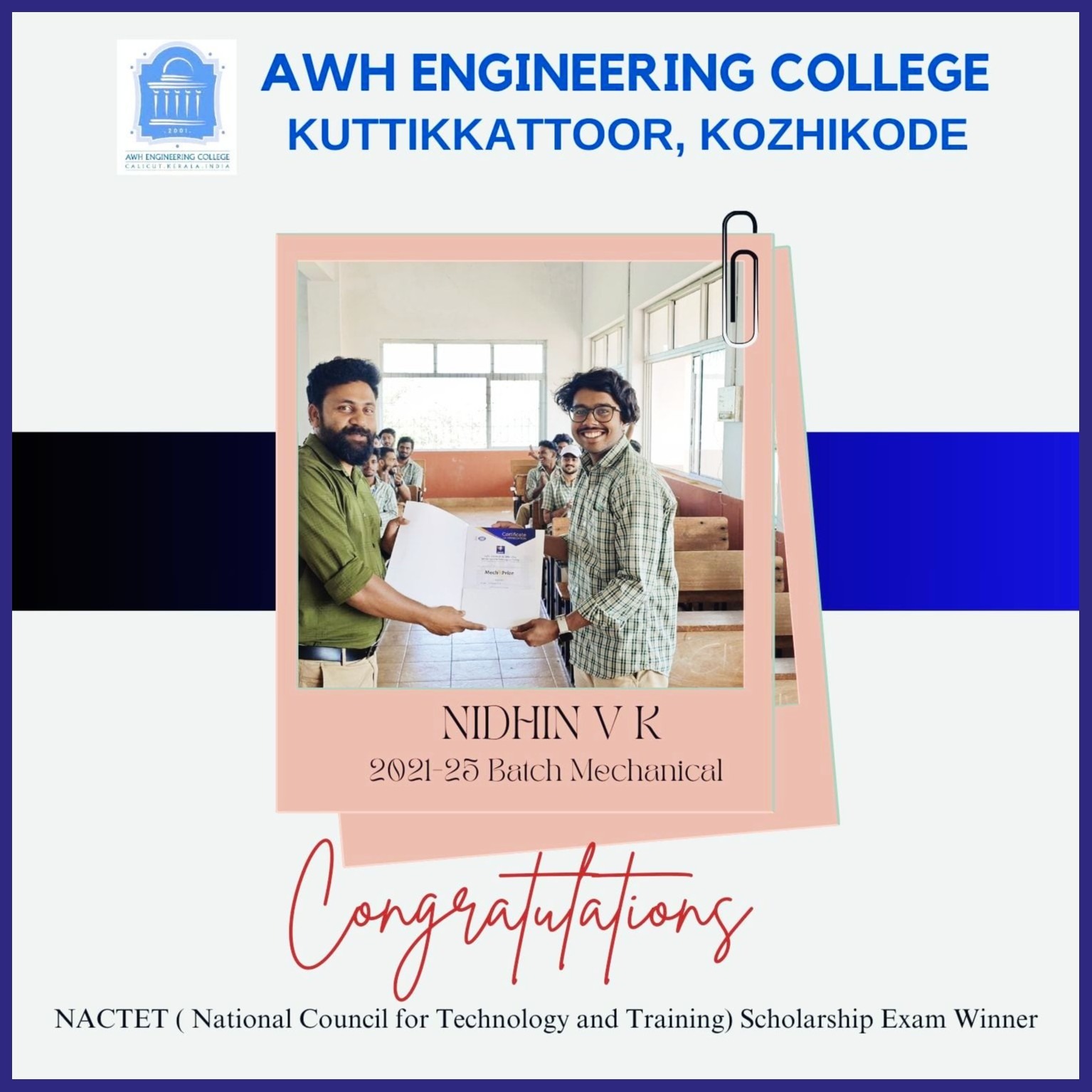

The Department of Mechanical Engineering proudly congratulates Nidhin V K (Batch 2021–2025) for successfully completing his B.Tech in Mechanical Engineering with a Minor in Electronics and Communication Engineering.

Mechanical Engineering Department Congratulate B-Tech toppers 2021-2025 Batch

The Mechanical Engineering Department congratulates the B.Tech S5 toppers of the 2022-2026 batch on their outstanding academic achievement.

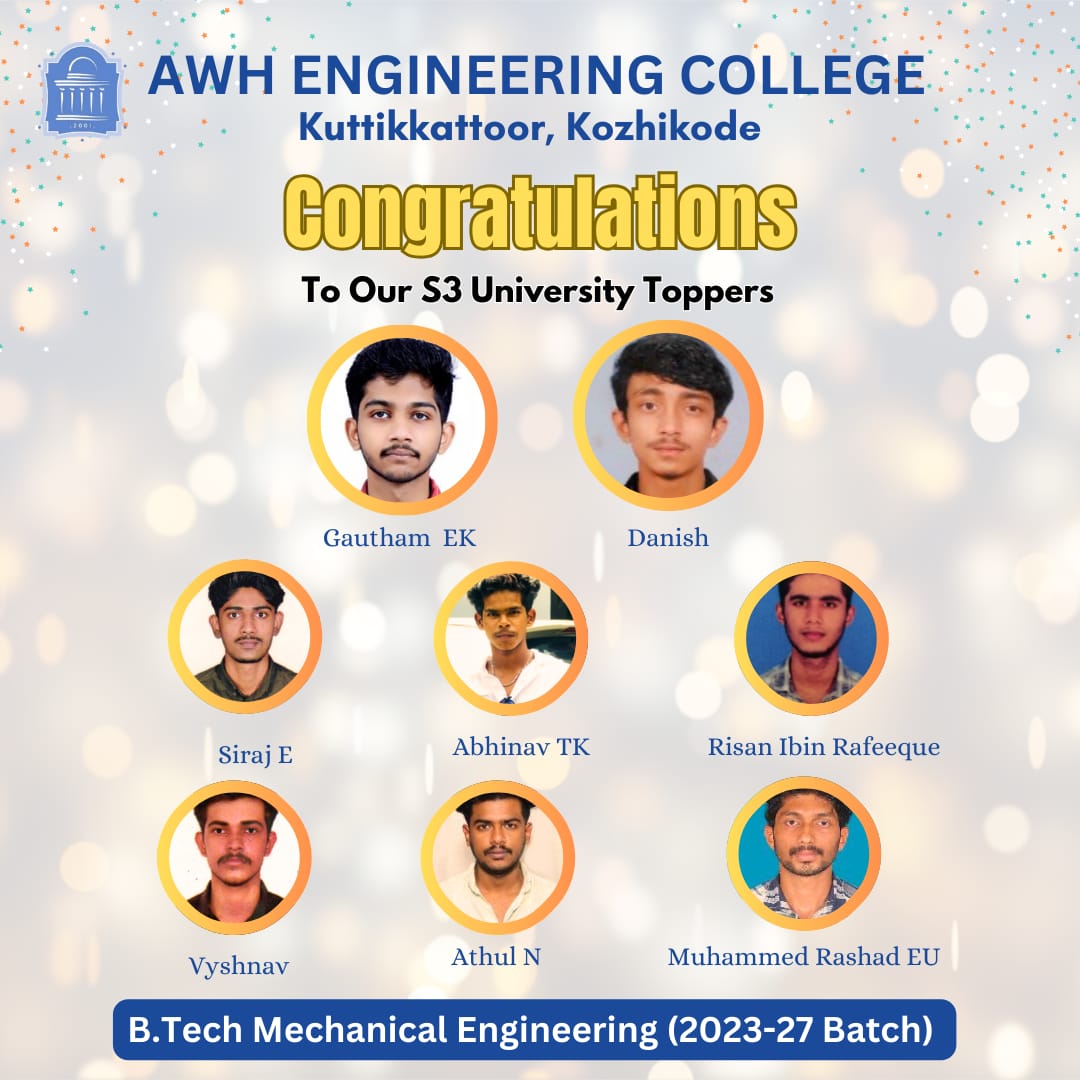

The Mechanical Engineering Department congratulates the B. Tech S3 toppers of the 2023-2027 batch on their outstanding academic achievement.

The Mechanical Engineering Department signed a Memorandum of Understanding (MoU) with Tech Shore Inspection Services on January 31, 2025, during the 2024-2025 academic year. This collaboration aims to enhance students' knowledge and skills in Quality Control (QC), Welding Inspection, Piping, and Pipeline Engineering.

2021-2025 batch achieved an impressive 89.65% pass percentage result in the seventh-semester B. Tech university examination held in November 2024. Congratulations to all.

Mr. Nidhin V K, from the 2021-2025 Mechanical Engineering batch, has been recognized as a National Council for Technology and Training Scholarship winner.

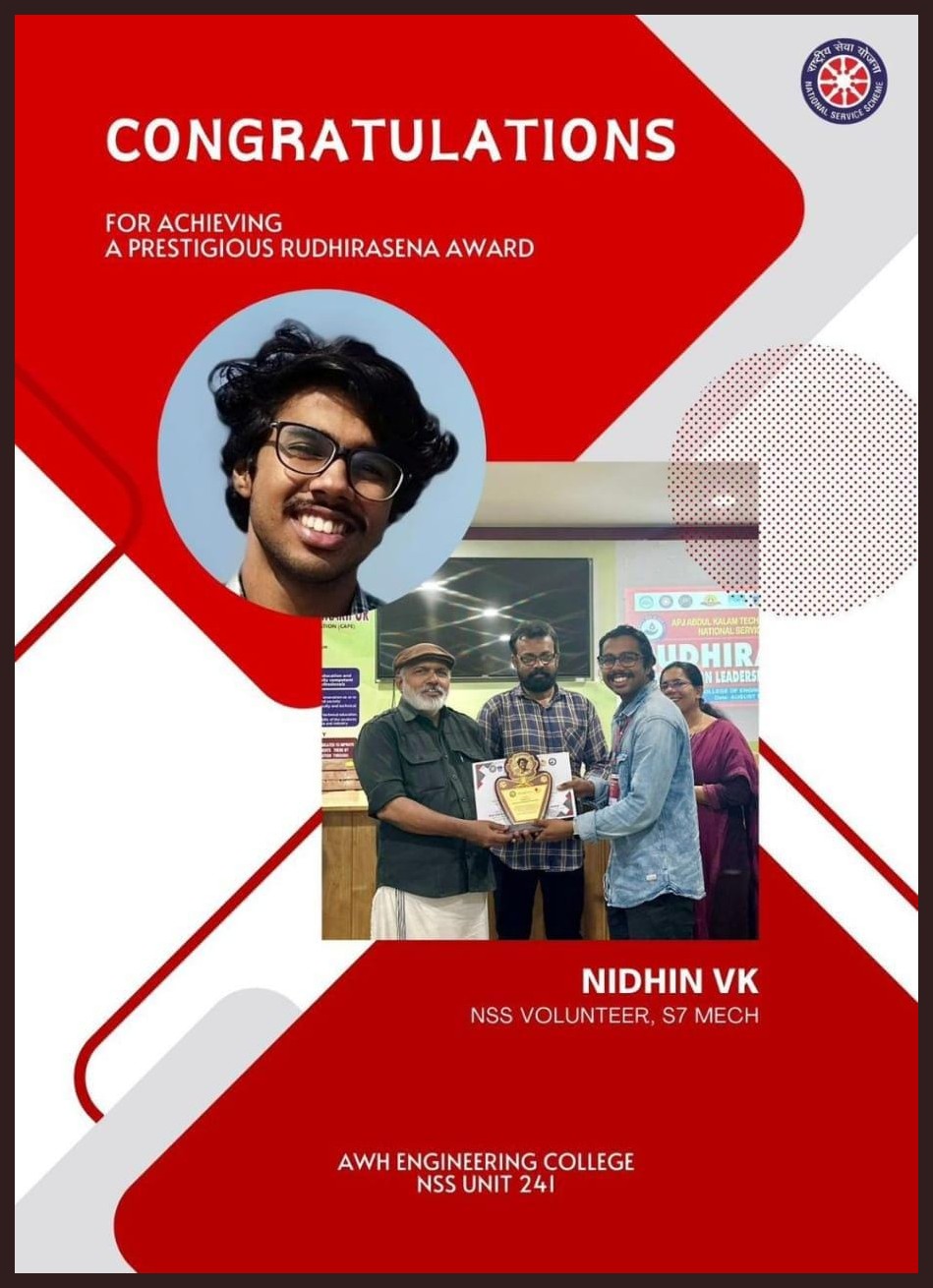

Congratulations NIDHIN VK 2021-2025 batch for achieving a prestigious Rudhirasena award

Interaction with outside world

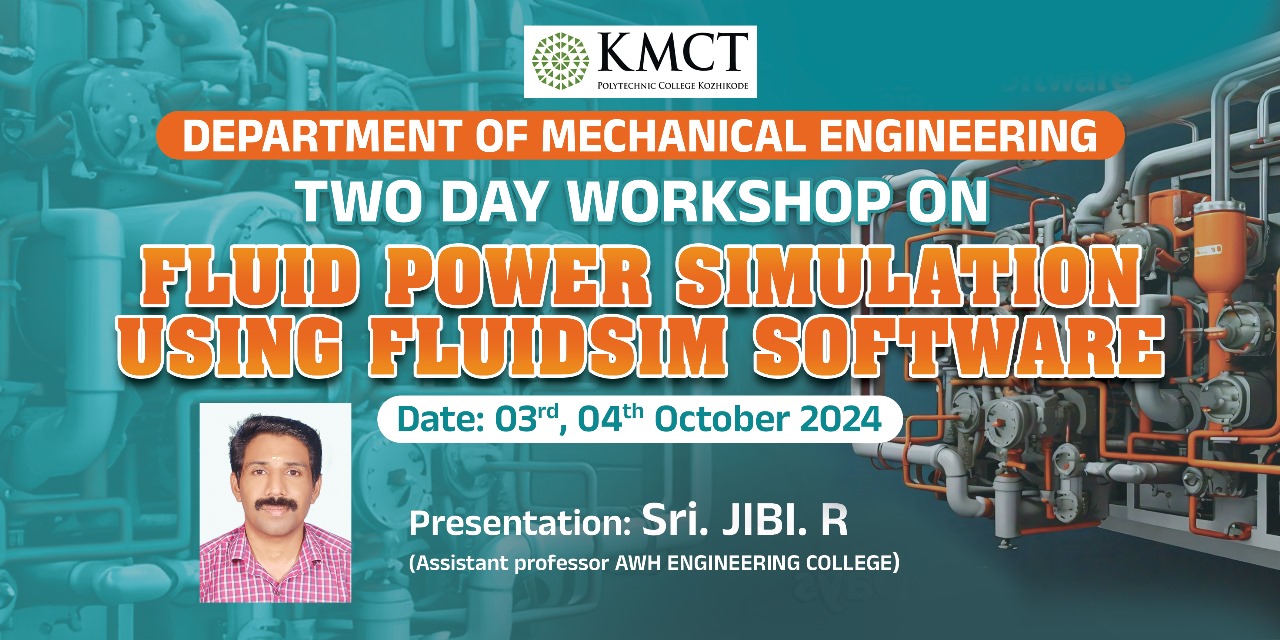

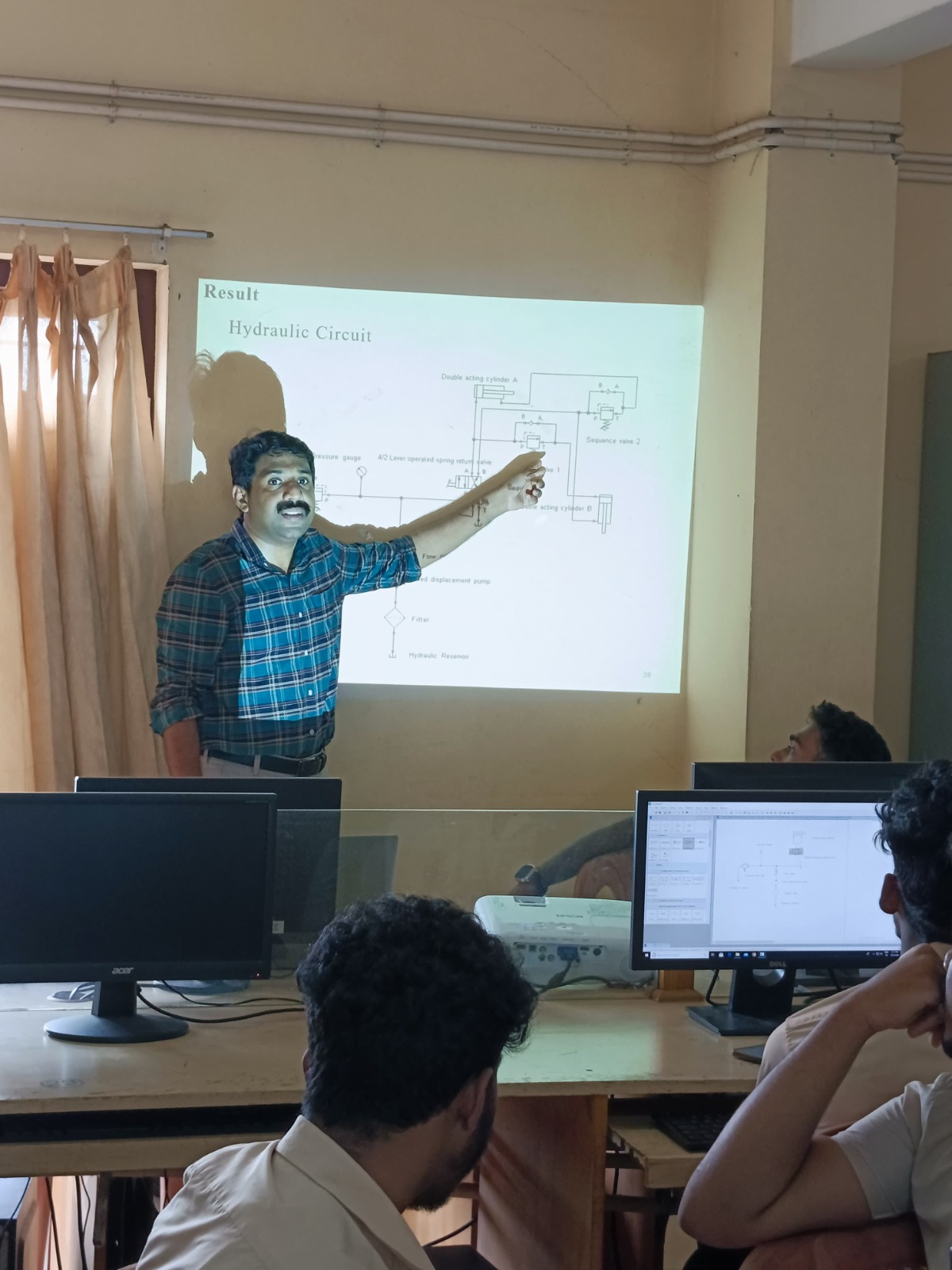

Mr. Jibi R, Assistant Professor, Department of Mechanical Engineering, conducted a workshop on "Fluid Power Simulation Using FluidSIM Software" organized by the Department of Mechanical Engineering, KMCT Polytechnic, Calicut, on 3rd and 4th October 2024.

AY 2023-2024

Placement Details 2020-2024 Batch

| Sl No | Student Name | Designation | Company Name |

|---|---|---|---|

| 1 | Mr. Sreeragh T | Mechanical Engineering Trainee | Forbes Marshall, Pune-Mumbai |

| 2 | Mr. Athul P E | Assistant Executive in Production | Veekesy Elastomers Pvt Ltd, Malappuram, Kerala |

| 3 | Mr. Nived C K | Assistant Executive in Production | Veekesy Elastomers Pvt Ltd, Kinalur, Kerala |

| 4 | Mr. Rinil | Trainee - Research and Development Department | ETA Technologies Pvt Ltd, Bengaluru, Karnataka |

| 5 | Mr. Aswin V K | Shift In-charge Trainee | Rapture India Footcare Pvt Ltd, Perumanna, Calicut |

| 6 | Mr. Shaham Ahammed K | Jr. Engineer - Trainee | Kairali Steels and Alloys Pvt Ltd, Kanjikode, Palakkad |

| 7 | Mr. Abhijith Babu | Engineer - Packaging | CEEKAY MULTI SERVICES, Mumbai |

| 8 | Mr. Abhishek P | Shift Engineer | MARK Radiant Molds and Compounds Pvt Ltd, Calicut |

| 9 | Mr. Sathar Khalid | Trainee Engineer | Valad Infotech Solutions Pvt, Mumbai |

| 10 | Mr. Amal P K | Jr. Engineer - Trainee | Kairali Steels and Alloys Pvt Ltd, Kanjikode, Palakkad |

Mechanical Engineering Department Congratulate B-Tech toppers 2020-2024 Batch

AY 2022-2023

Placement Details 2019-2023 Batch

| Sl No | Student Name | Designation | Company Name |

|---|---|---|---|

| 1 | Mr. Jithin P | Analyst | Satyam Venture Engineering Services Private Limited |

| 2 | Mr. Vishak M K | CAE Modeler | CADFEM India Pvt Ltd |

| 3 | Mr. Faris Bin Basheer | Marketing Manager | Wabco Shipping Company Ltd |

| 4 | Mr. Giyad M | Mechanical Engineer | JAL Engineering Services L.L.C, Oman, Muscat |

| 5 | Mr. Harshak CP | Team Leader | Bharti Airtel Limited |

| 6 | Mr. Rohan Prakash | Assistant Executive in Production | Walkaroo International Pvt Ltd |

| 7 | Mr. Anumythrey T | CAE Analyst Engineer | COPES Tech India Pvt Ltd / L&T Technology Services |

| 8 | Mr. Muhammad Munshif T T | Quality Assurance of Incoming Process & Defect Root Cause Analyst | ZF Commercial Vehicle Control Systems India Limited |

| 9 | Mr. Abhinand R S | CAE Engineer | COPES Tech India Pvt Ltd |

Magazine/Newsletter

Mechanical Engineering Department Newsletter

Welcome to the Mechanical Engineering Department Newsletter! This newsletter serves as a chronicle of the exciting events, significant accomplishments, and ongoing activities that have shaped our department. It is a platform for us to share our successes, celebrate our achievements, and strengthen the bonds that unite us as a Mechanical Engineering Department.

Students Publications and Projects

Publications

| Month & Year | Student Name | Publication/Conference Details |

|---|---|---|

| April 2025 | Mr.Amar Goutham T Mr.Karthik M Mr.Vyshnav P Mr.Mohammed Roshan |

“Design and Fabrication of Speed Breaker Electricity Generator” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025. |

| April 2025 | Mr.Athul V Mr.Ajith V S Mr.Amruthesh K T |

“Comparative Evaluation of Welding Defects in TIG and MIG Joints using Non-Destructive Testing (NDT) Methods” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025. |

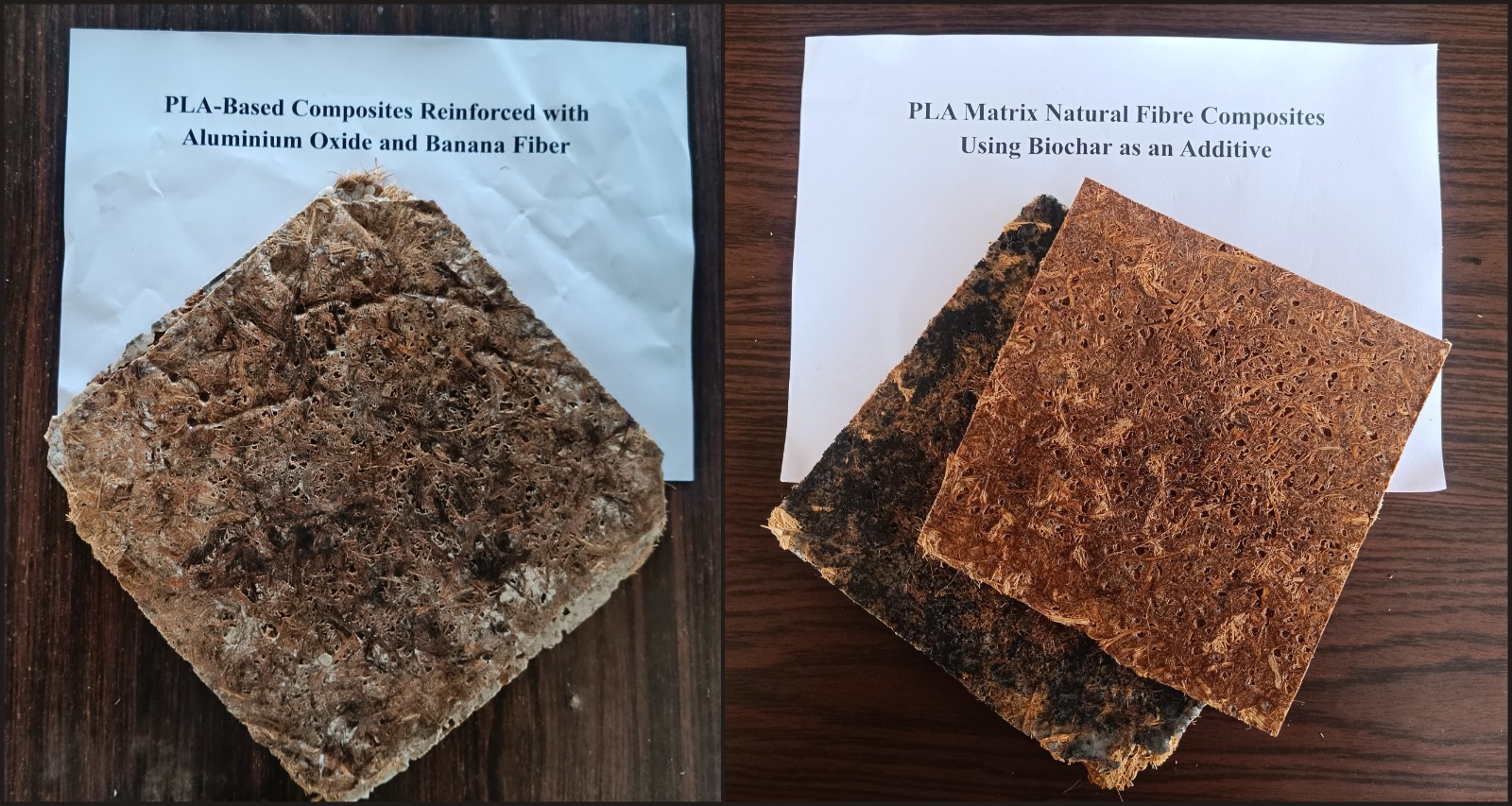

| April 2025 | Mr.Mohammed Aman E K Mr.Sreehari S Mr. Anujith K Mr.Rohit Sasikumar |

“Investigation of Mechanical and Thermal Properties of PLA Matrix Natural Fibre Composites using Biochar as an Additive” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025. |

| April 2025 | Mr.Ajmal Siras E Mr. Manave Mr.Nidhin V Mr. Abhiram S |

“Evaluation of Mechanical Characteristics and Thermal Stability of PLA-Based Composites Reinforced with Aluminium Oxide and Banana Fiber” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025 |

| March 2025 | Mr.Athif Ahammed Kutty Mr.Yadunandhan S G Mr. Kasinath P K MMr.Abishek K |

“Developing a Sequential Pneumatic Circuit for Sheet Metal Operations Using Multiple Pneumatic Actuators” International Research Journal of Engineering and Technology (IRJET) Volume: 12 Issue: 03, March 2025 |

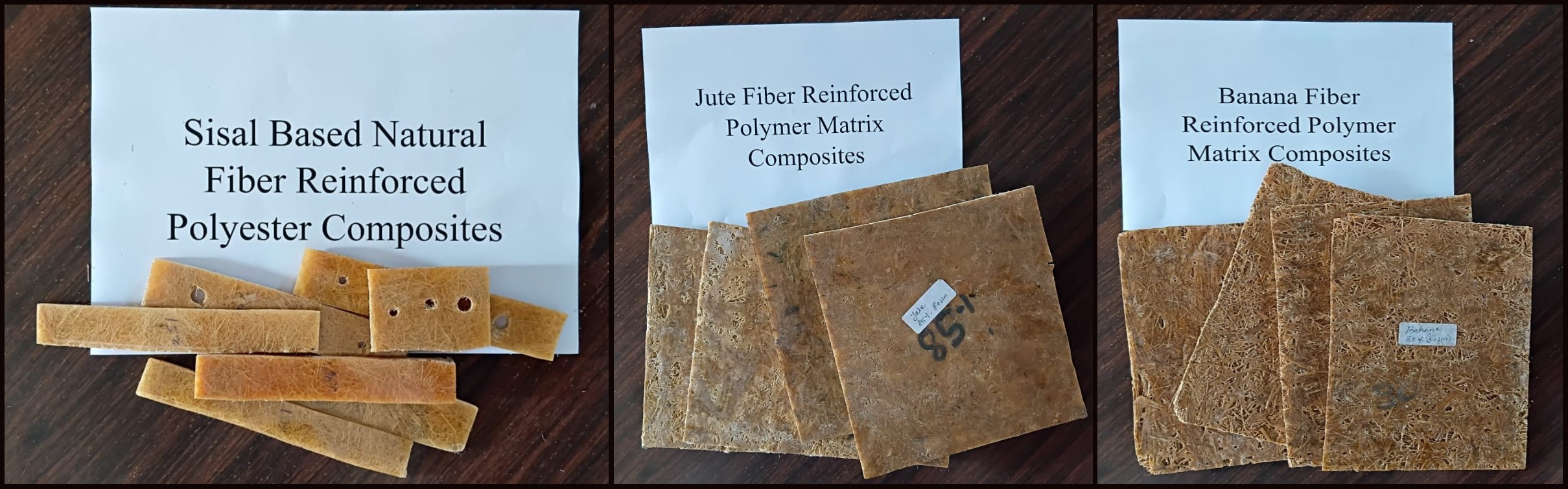

| May 2024 | Mr. Abdul Basith MK Mr. Sathar Khalid MC Mr. Sooraj AT |

“Optimization of Process Parameters for Drilling Sisal Fiber-Reinforced Polyester Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 5, May 2024. |

| May 2024 | Mr. Abhishek P Mr. Akshay Anand P S Mr. Aswin V K |

“Parametric Optimization of TIG welding and Defect Identification using Non-Destructive Testing Methods” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 5, May 2024. |

| May 2024 | Mr. Sreeragh T Mr. Rishith M K Mr. Karthika C Mr. Vishnu Raj M |

“Failure and Rectification of Double Stage Double Acting Reciprocating Air Compressor” International Research Journal of Engineering and Technology (IRJET) Volume, 11 Issue, 05 May 2024. |

| April 2024 | Mr. Rinil Mr. Mijuwad P P Mr. Adwaith A Mr. Anaj T |

“A Comprehensive Examination of Defect in Continuous Cast Billet and Analysis Using Quality Control Tool” International Research Journal of Engineering and Technology (IRJET) Volume: 11 Issue: 04 Apr 2024. |

| April 2024 | Mr. Athul PE Mr. Adithyan KR Mr. Rithik Raj VV Mr. Shaham Ahammed K |

“Mechanical Characterization of Banana Fiber Reinforced Polymer Matrix Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 4, April 2024. |

| April 2024 | Mr. Abhijith Babu P Mr. Abhinand P Mr. Abhinav Anish C Mr. Adeeb Danish AM |

“Investigation of Vibration and Damping Characteristics of Sisal Based Natural Fiber Reinforced Polyester Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 4, April 2024. |

| April 2024 | Mr. Nived C K Mr. Afham T Mr. Rohith M K Mr. Vishnu K V |

“Mechanical Properties of Jute Fiber Reinforced Polymer Matrix Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 4, April 2024. |

| March 2024 | Mr. Muhammed Ishak V Mr. Ahammed Adil P Mr. Amal P K Mr. Rohith V T |

“Design Simulation and Development of Sequential Pneumatic Circuit for Industrial Applications” International Research Journal of Engineering and Technology (IRJET) Volume: 11 Issue: 03 March 2024. |

| March 2024 | Mr. Muhammed Ishak V Mr. Ahammed Adil P Mr. Amal P K Mr. Rohith V T |

“Design and Simulation of Electro-Pneumatic Sequential System Using Fluid Sim Software” International Research Journal of Engineering and Technology (IRJET) Volume: 11 Issue: 03 March 2024. |

| April 2022 | Mr. Nithin P Mr. Shijin NC Mr. Abhishek O Mr. Aswanth S S |

“Development of Boring Fixture for Lathe Machine Tool and Application of Flow Process Chart” International Journal of Engineering and Innovative Technology (IJEIT) Volume 11, Issue 10, April 2022. |

| September 2020 | Mr. Abdulla Adhil C Mr. Akhil Muhammed Mr. Jithin P Mr. Navag Pradeep |

“Designing and analysis of lifting eye bolt for various geometry” International Journal of Engineering and Innovative Technology (IJEIT) Volume 10, Issue 3, September 2020. |

| May 2020 | Mr. Pranav Mr. Niyas M A Mr. Akshay P Mr. Asmilsha Rahman A. P |

“Designing and Modeling of Gating System and Feeder for Brass Flange Casting” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 11, May 2020. |

| May 2020 | Mr. Akshay. K Mr. Thejas.S Mr. Vaishnav Mr. Ajmal Roshan P. P |

“Design Analysis and Development of Draw Die for Cylindrical Cup formation” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 11, May 2020. |

| April 2020 | Mr. Raswin A C Mr. Ubaid E Mr. Ajeesh V |

“Integrating CAD/CAE Design Technology for Design and Analysis of Bending Tool” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 10, April 2020. |

| April 2020 | Mr. Ashique N K Mr. Shijil K V Mr. Pranav N Sarath Mr. Ahamed Akhid |

“Application of Conceptual Design for Modeling and Analysis of Leaf Jig” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 10, April 2020. |

| September 2019 | Mr. Vishnu Das M Mr. Harikrishna T K Mr. Aswin T Mr. Vishnu M |

“Productivity Enhancement through Design and Development of Milling Fixture” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 3, September 2019. |

| January 2017 | Mr. Fahim Muhammed Mr. Muhammad Raazick Mr. Noorshan Mr. Rashid K Miss. Rumaisa C M Mr. Sanmishal P K |

“Energy Efficiency Analysis of an Industrial Reheating Furnaces and Investigating Efficiency Enhancing Opportunities: Literature Review” International Journal of Engineering and Innovative Technology (IJEIT) Volume 6, issue 6, January 2017. |

| May 2016 | Mr. Muhammed Raazick Mr. Noorshan Mr. Rashid K R Miss. Rumaisa C M Mr. San Mishal P K |

“Defect Reduction in an Arc Welding Process Using Cause and Effect Diagram” International Journal of Engineering and Innovative Technology (IJEIT) Volume 5, Issue 11, May 2016. |

| February 2015 | Mr. KP Faisal Mr. Falah Ummer Mr. KC Hareesh Mr. Munavir Ayaniyat Mr. K Nijab Mr. P Nikesh |

“Analysis and Simulation of Crankshaft Manufacturing Unit Using Arena” International Journal of Scientific and Research Publications, Volume 5, Issue 2, February 2015 ISSN 2250-3153. |

| January 2015 | Mr. KP Faisal Mr. Falah Ummer Mr. KC Hareesh Mr. Munavir Ayaniyat Mr. K Nijab Mr. P Nikesh |

“Application of Process FMEA and Discrete Event Simulation in a Crank Shaft Manufacturing Unit” International Journal of Emerging Technology and Advanced Engineering, Volume 5, Issue 1, January 2015. |

| January 2015 | Mr. KP Faisal Mr. Falah Ummer Mr. K C Hareesh Mr. Munavir Ayaniyat Mr. K Nijab Mr. P Nikesh |

“Application of FMEA Method in a Manufacturing Organization focused on Quality” International Journal of Engineering and Innovative Technology (IJEIT), Volume 4, Issue 7, January 2015. |

| February 2014 | Mr. Cigil Sebastian Mr. Nidhin Babu AV Mr. Rajneesh P Mr. Sinosh NK Mr. Sreeraj E |

“Improving Production Performance through Lean Manufacturing Techniques in a Manufacturing Firm” in International Journal of Emerging Technology & Advanced Engineering (ISSN 2250-2459, ISO 9001:2008 Certified Journal), Volume 4, Issue 2, February, 2014. |

Projects

AY 2024-2025

| Group No | Register No | Name | Title of The Project |

|---|---|---|---|

| Group 1 | AWH21ME003 | AMAR GOUTHAM T | Design and Fabrication of Speed Breaker Electricity Generator |

| AWH21ME010 | KARTHIK M | ||

| AWH21ME018 | VYSHNAV P | ||

| AWH20ME017 | MUHAMMED ROSHAN | ||

| Group 2 | AWH21ME002 | AJMAL SIRAS E P | Evaluation of Mechanical Characteristics and Thermal Stability of PLA-Based Composites Reinforced with Aluminium Oxide and Banana Fiber |

| AWH21ME011 | MANAVE VAZHAYIL | ||

| AWH21ME015 | NIDHIN V K | ||

| LAWH21ME020 | ABHIRAM S J | ||

| Group 3 | AWH21ME001 | ABISHEK K | Developing a Sequential Pneumatic Circuit for Sheet Metal Operations Using Multiple Pneumatic Actuators |

| AWH21ME007 | ATHIF AHAMMED KUTTY | ||

| AWH21ME019 | YADUNANDHAN S G | ||

| LAWH21ME025 | KASINATH P K | ||

| Group 4 | AWH21ME013 | MUHAMMED AMAN ROSHAN A T | Design and Fabrication of Electro-Magnetic Breaking System |

| AWH21ME014 | MUHAMMED HAMRAS C K | ||

| LAWH21ME022 | AMRIDJITH K | ||

| LAWH21ME027 | MUHAMMED SHAREEF C V | ||

| Group 5 | AWH21ME012 | MOHAMMED AMAN E K | Investigation of Mechanical and Thermal Properties of PLA Matrix Natural Fibre Composites using Biochar as an Additive |

| AWH21ME016 | SREEHARI S | ||

| LAWH21ME023 | ANUJITH K | ||

| LAWH21ME029 | ROHIT SASIKUMAR | ||

| Group 6 | AWH21ME004 | AMRUTHESH K T | Comparative Evaluation of Welding Defects in TIG and MIG Joints Using Non Destructive Testing (NDT) Methods |

| LAWH21ME021 | AJITH V S | ||

| LAWH21ME024 | ATHUL V | ||

| Group 7 | AWH21ME008 | BASIM MUHAMMED I | Design and Fabrication of Compressed Air Production Using Vehicle Suspension |

| LAWH21ME026 | MOHAMMED JABIR ASHRAF KOYA | ||

| LAWH21ME028 | PRITHWIRAJ K B | ||

| Group 8 | AWH21ME006 | ASHISH PRASANTH K T | Analysis of Relation Between Types of Drives and State of Charge on Electric Vehicle |

| KSD21ME021 | YADU GOVIND J N | ||

| AWH21ME005 | ARUN THOMAS |

AY 2023-2024

| Group No | Register No | Name | Title of The Project |

|---|---|---|---|

| Group 1 | AWH20ME001 | ABHIJITH BABU P | Investigation of Vibration and Damping Characteristics of Sisal Based Natural Fiber Reinforced Polyester Composites |

| AWH20ME002 | ABHINAND P | ||

| AWH20ME004 | ADEEB DANISH A M | ||

| AWH20ME003 | ABHINAV ANISH C | ||

| Group 2 | AWH20ME013 | ATHUL P E | Mechanical Characterization of Banana Fiber Reinforced Polymer Matrix Composites |

| AWH20ME024 | RITHIK RAJ V V | ||

| AWH20ME027 | SHAHAM AHAMMED K | ||

| AWH20ME005 | ADITHYAN K R | ||

| Group 3 | AWH20ME023 | RINIL | A Comprehensive Examination of Defect in Continuous Cast Billet and Analysis Using Quality Control Tool |

| AWH20ME016 | MIJUWAD P P | ||

| AWH20ME012 | ANAJ T | ||

| AWH20ME006 | ADWAITH A | ||

| Group 4 | AWH20ME022 | NIVED C K | Mechanical Properties of Jute Fiber Reinforced Polymer Matrix Composites |

| AWH20ME030 | VISHNU K V | ||

| AWH20ME025 | ROHITH M K | ||

| AWH20ME007 | AFHAM T | ||

| Group 5 | AWH20ME019 | MUHAMMED ISHACK V | Design Simulation and Development of Sequential Pneumatic Circuit for Industrial Applications |

| AWH20ME026 | ROHITH V T | ||

| AWH20ME008 | AHAMMED ADIL P | ||

| AWH20ME010 | AMAL P K | ||

| Group 6 | LAWH20ME036 | AMITH TK | Analysis of Corrosion in Pipe Line Materials. |

| AWH20ME028 | SIVANG V | ||

| LAWH20ME038 | JIDHU KRISHNAN E | ||

| AWH20ME014 | C ABDUL BASITH | ||

| Group 7 | LAWH20ME044 | SREERAGH T | Failure and Rectification of Double Stage Double Acting Reciprocating Air Compressor |

| AWH20ME031 | VISHNU RAJ M | ||

| LAWH20ME042 | RISHITH M K | ||

| AWH20ME015 | KARTHIKA C | ||

| Group 8 | LAWH20ME040 | NIHAL KK | Heat Transfer Perfomance analysis of Heat Exchanger |

| AWH20ME032 | VYSHNAV VIJAYAKRISHNAN K | ||

| LAWH20ME041 | RAHUL K | ||

| AWH20ME018 | MUHAMMED FAYIS K T | ||

| Group 9 | LAWH20ME034 | ABHISHEK P | Parametric Optimization of TIG Welding and Defect Identification using Non Destructive Testing Methods |

| LAWH20ME035 | AKSHAYANAND P.S | ||

| LAWH20ME037 | ASWIN V.K | ||

| Group 10 | LAWH20ME033 | ABDUL BASITH M K | Optimization of Process Parameters for Drilling Sisal Fiber-Reinforced Polyester Composites |

| AWH20ME029 | SOORAJ A T | ||

| LAWH20ME043 | SATHAR KHALID M C |

AY 2022-2023

| Group No | Register No | Name | Title of The Project |

|---|---|---|---|

| Group 1 | AWH19ME001 | ABDURAHMAN NIAZ ABDURAHMAN | Construction and Thermal Analysis of Thermo Electric Power Generation System |

| AWH19ME004 | ADITHYA NARAYAN | ||

| AWH19ME012 | FARIS BIN BASHEER | ||

| AWH19ME020 | MUHAMMED ISMAYIL U | ||

| Group 2 | LAWH19ME042 | JUBIN P K | Magnetor Rheological Breaking System |

| LAWH19ME045 | SHILJITH A | ||

| LAWH19ME034 | AJAY KRISHNAN | ||

| AWH19ME013 | GIYAD | ||

| Group 3 | AWH19ME025 | ROHAN PRAKASH | Vortex Bladeless Windmill Power Generation |

| AWH19ME002 | ABHINAND R S | ||

| AWH19ME007 | ANUMYTHREY T | ||

| AWH19ME008 | ARJUN V | ||

| Group 4 | AWH19ME014 | HANIN THARIQUE | Fabrication of Solar Water Reciprocating Pump |

| AWH19ME019 | MUHAMMED IMTHIYAS P N | ||

| AWH19ME015 | HARSHAK C P | ||

| AWH19ME021 | MUHAMMED JAHANGEER P | ||

| Group 5 | LAWH19ME035 | ANUGRAH M | Pneumatic Zero Turning Vehicle |

| LAWH19ME039 | JITHIN P | ||

| LAWH19ME040 | JITHIN RAJ K | ||

| LAWH19ME048 | YADHU KRISHNAN E | ||

| Group 6 | AWH19ME011 | DILSHAD M | Design and Fabrication of Automatic Hydraullic Jack to Inbuild in FourWheeler |

| AWH19ME005 | AJUL M | ||

| AWH19ME028 | SUCHETH K BROWN | ||

| AWH19ME023 | MUHAMMED MUNSHIF T T | ||

| Group 7 | AWH19ME026 | ROSHAN K | Solar Autotracking |

| AWH19ME018 | MUHAMMED FIRDOUSE P | ||

| AWH19ME024 | PRITHVINATH T | ||

| LAWH19ME044 | RAKESH T.P | ||

| Group 8 | LAWH19ME046 | SIYAD P | Hydro Pneumatic Moving Vehicle |

| LAWH19ME032 | ABDUL FARIS K.K | ||

| AWH19ME003 | ABHISHEKLAL M | ||

| LAWH19ME033 | ADITHYA SUKUMARAN | ||

| Group 9 | LAWH19ME036 | ASWANTH PK | Bluetooth Controlled Solar Grass Cutting Maching |

| LAWH19ME041 | JITHU K | ||

| LAWH19ME047 | VISHAK MK | ||

| AWH19ME027 | SHAFNAS V K | ||

| Group 10 | AWH19ME022 | MUHAMMED MUBASHIR T | Multistage Sand Filter |

| AWH19ME016 | JAIYUSH KUNDOOR | ||

| AWH19ME006 | AMAL | ||

| AWH19ME017 | KAMIL MOHAMMED T K | ||

| AWH19ME029 | WAFIQ AHAMED P V |

R&D

The Department of Mechanical Engineering drives innovation through cutting-edge research, fosters interdisciplinary collaborations, and develops sustainable technologies to address global challenges.

Our mission is to drive innovation in mechanical engineering by conducting impactful student projects, fostering interdisciplinary collaborations, and creating sustainable solutions to address global challenges.

Our vision is to become a hub of excellence in mechanical engineering education and research, where student projects and interdisciplinary innovation lead the way in creating sustainable solutions for the world’s challenges.

Our Research Focus

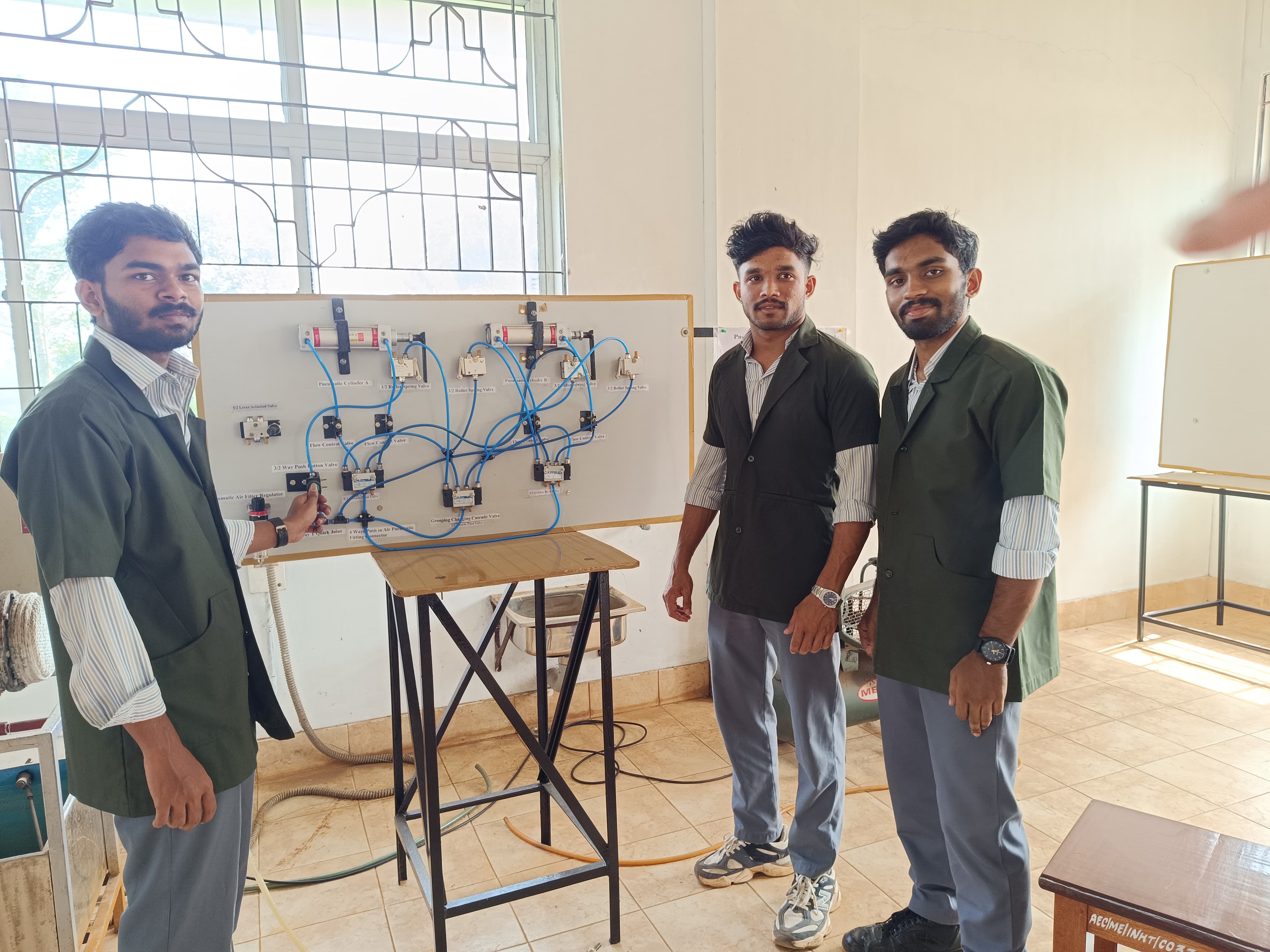

Innovating Fluid Power Systems

Automation plays a vital role in the Fourth Industrial Revolution, transforming how industries operate. It involves the science and engineering of designing and building mechanisms for real-life applications. Automation is broadly defined as the use of control systems, such as pneumatics, hydraulics, electrical, electronic, and computer-based systems, to control industrial machinery and processes, thereby minimizing the need for human intervention. In modern industries, pneumatic systems are increasingly favored over hydraulics and electromotive systems. This is due to the continuous availability of compressed air and their ability to operate safely in flammable conditions without the risk of ignition or explosion. Pneumatic systems are also valued for their simplicity, reliability, and versatility in various applications. Recently, the Mechanical Engineering Department has developed a functional prototype of a pneumatic sequence circuit: A+B+B-A-.This model demonstrates the potential of pneumatic systems in achieving precise and reliable automation for industrial processes. In multicylinder applications, the A+B+B-A- sequence finds wide applications, particularly in operations like sheet metal processing in a press shop. One such example is a stamping operation performed using a stamping machine. In this process:

- The workpiece is first clamped securely under the stamping station.

- The stamping tool then moves into position and performs the stamping operation.

- The workpiece is unclamped only after the stamping operation is fully completed.

The cascade system offers a straightforward and efficient method for designing sequential circuits to ensure proper operation of such systems. This method allows precise control of the sequence, ensuring safety, reliability, and operational accuracy.

During the academic year 2024-2025, the Mechanical Engineering Department developed a functional prototype model of a pneumatic sequence circuit (A+B+B-C+C-A-). This system has wide applications in multicylinder operations. The pneumatic system consists of multiple actuators used for performing sheet metal operations such as clamping, bending, and forming. In the process, a metal strip is manually placed in a fixture of the bending machine. When a push button is pressed, Cylinder A clamps the metal strip. Cylinder B then initiates the bending operation and retracts, followed by Cylinder C completing the operation. Once Cylinder C returns to its initial position, Cylinder A releases the finished part.

Exploring Composite Advancements

Composite materials are advanced materials engineered by combining two or more constituent materials with distinct physical or chemical properties. By merging these materials, composites achieve unique and often superior characteristics compared to their individual components.

Typically, composites consist of fibers—such as glass, carbon, or aramid—embedded in a matrix, often a polymer resin. The fibers provide strength and stiffness, while the matrix binds them together and facilitates load transfer.

Composites are widely utilized in industries such as aerospace, automotive, marine, and construction due to their lightweight nature, high strength-to-weight ratio, corrosion resistance, and versatility. Notable examples include carbon fiber composites in aircraft structures and fiberglass-reinforced plastics in boat hulls.

Recently, our department has developed Sisal-Based Natural Fiber Reinforced Polyester Composites, Jute Fiber Reinforced Polymer Matrix Composites, and Banana Fiber Reinforced Polymer Matrix Composites.These advancements highlight our commitment to exploring sustainable materials and contributing to the growing field of natural fiber-reinforced composites.

During the academic year 2024–2025, the Department of Mechanical Engineering undertook significant research initiatives in the development of sustainable and high-performance composite materials. Two major composite systems were developed as part of the department’s commitment to innovation in material science:

- Development of PLA Matrix Natural Fibre Composites Using Biochar as an Additive. A novel biodegradable composite was developed using Polylactic Acid (PLA) as the matrix and biochar as an additive. Biochar, a carbon-rich material obtained from the thermochemical conversion of biomass under a nitrogen atmosphere, was incorporated into the PLA matrix to enhance both mechanical and thermal properties of the composite.

- PLA-Based Composites Reinforced with Aluminium Oxide and Banana Fiber Another key development involved the fabrication of a biodegradable composite using PLA reinforced with Aluminium Oxide (Al₂O₃) and banana fiber.

MoU

- The Mechanical Engineering Department signed a Memorandum of Understanding (MoU) with Tech Shore Inspection Services on January 31, 2025, during the 2024-2025 academic year. This collaboration aims to enhance students' knowledge and skills in Quality Control (QC), Welding Inspection, Piping, and Pipeline Engineering.

- ME Dept signed MoU with Scale up Mission during 2022-2023 academic year for up-skilling the students of college under subscription of scale up mission internship program and providing opportunities for CAE training and jobs.

Faculty Publication

| Month & Year | Faculty Name | Publication/Conference Details |

|---|---|---|

| May 2025 | Dr. Sreeram D Associate Professor |

“Metallurgical Bonding, Interfacial Chemistry, and Mechanical Optimization of Dissimilar AA7079–AA6063 Welds via Response Surface Methodology” international Journal of Multidisciplinary Research Malaysian Journal of Chemistry, 2025, Vol. 27(3), 543-556 (Special Issue: International Conference on Sustainable Materials and Technologies, ICSMT 2025). |

| April 2025 | Mr. Kiran Murali P Assistant Professor |

“Design and Fabrication of Speed Breaker Electricity Generator” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025 |

| April 2025 | Mr. Safeer M Assistant Professor |

“Comparative Evaluation of Welding Defects in TIG and MIG Joints using Non-Destructive Testing (NDT) Methods” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025. |

| April 2025 | Mr. Nikhil K V Assistant Professor |

“Investigation of Mechanical and Thermal Properties of PLA Matrix Natural Fibre Composites using Biochar as an Additive” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025. |

| April 2025 | Dr. Sreeram D Associate Professor |

“Evaluation of Mechanical Characteristics and Thermal Stability of PLA-Based Composites Reinforced with Aluminium Oxide and Banana Fiber” international Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 14, Issue 4, April 2025. |

| March 2025 | Mr. Jibi. R Assistant Professor |

“Developing a Sequential Pneumatic Circuit for Sheet Metal Operations Using Multiple Pneumatic Actuators” International Research Journal of Engineering and Technology (IRJET) Volume: 12 Issue: 03, March 2025. |

| December 2024 | Dr. Ajmal T. S. Associate Professor |

“SELF-OPERATING SMART TELESCOPIC FORK ASSEMBLY”, Indian Patent/Design No.: 432386-001, Date: 01/10/2024, Date of Issue: 11/12/2024, Controller General of Patents, Design and Trade Marks, The Patent Office, Government of India |

| November 2024 | Mr. Nikhil K V Assistant Professor |

“Sisal fiber reinforced PLA Nanocomposites with improved Mechanical Thermal and Morphological Properties” Nanotechnology Perceptions 20 No. 6 (2024) 1383-1398, November 2024. |

| September 2024 | Dr. Ajmal T. S. Associate Professor |

“Enhancing the Flow Accelerated Corrosion Resistance of X70 API Steel Through Laser Surface Melting in Synthetic Oilfield Water”, Materials and Corrosion, 2024; 1–13 See More |

| May 2024 | Dr. T S Ajmal Associate Professor & Mr. Jibi. R Assistant Professor |

“Failure and Rectification of Double Stage Double Acting Reciprocating Air Compressor” International Research Journal of Engineering and Technology (IRJET) Volume, 11 Issue,05 May 2024. |

| May 2024 | Mr. Abhiram K Assistant Professor |

“Parametric Optimization of TIG welding and Defect Identification using Non-Destructive Testing Methods” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 5, May 2024. |

| May 2024 | Dr. Ajmal T. S. Associate Professor |

“AUTOMATED WHEEL ALIGNMENT AND PUNCTURE DETECTION SYSTEM ENHANCING VEHICLE SAFETY AND PERFORMANCE”, Indian Patent Application No.202441036988 A, Date of Publication: 17/05/2024, Controller of Patents, The Patent Office, Chennai |

| April 2024 | Mr. Jibi. R Assistant Professor |

“A Comprehensive Examination of Defect in Continuous Cast Billet and Analysis Using Quality Control Tool” International Research Journal of Engineering and Technology (IRJET) Volume: 11 Issue: 04 Apr 2024. |

| April 2024 | Mr. Nikhil K V Assistant Professor |

“Mechanical Characterization of Banana Fiber Reinforced Polymer Matrix Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 4, April 2024. |

| April 2024 | Dr. Sreeram D Associate Professor |

“Investigation of Vibration and Damping Characteristics of Sisal Based Natural Fiber Reinforced Polyester Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 4, April 2024. |

| April 2024 | Dr. Sreeram D Associate Professor |

“The mechanical and microstructural characterization of dissimilar welded AA 7075 and AA6101 by Friction Stir welding process” Revista Materia. |

| April 2024 | Dr. Sreeram D Associate Professor |

“Mechanical Properties of Jute Fiber Reinforced Polymer Matrix Composites” International Journal of Multidisciplinary Research in Science, Engineering and Technology (IJMRSET) Volume 7, Issue 4, April 2024. |

| March 2024 | Mr. Jibi. R Assistant Professor |

“Design Simulation and Development of Sequential Pneumatic Circuit for Industrial Applications” International Research Journal of Engineering and Technology (IRJET) Volume: 11 Issue: 03 March 2024. |

| March 2024 | Mr. Jibi. R Assistant Professor |

“Design and Simulation of Electro-Pneumatic Sequential System Using Fluid Sim Software” International Research Journal of Engineering and Technology (IRJET) Volume: 11 Issue: 03 Mar 2024. |

| January 2024 | Mr. Safeer M Assistant Professor |

“Analyzing transportation and distribution in emergency humanitarian logistics” Procedia engineering, Elsevier. |

| September 2023 | Dr. Ajmal T. S. Associate Professor |

“PNEUMATIC LIFTER”, Indian Patent/Design No.: 387246-001, Date: 29/05/2023, Date of Issue: 13/09/2023, Controller General of Patents, Design and Trade Marks, The Patent Office, Government of India |

| October 2022 | Dr. Ajmal T. S. Associate Professor |

“Effect of hydrodynamics and laser surface melting on erosion-corrosion of X70 steel pipe elbow in oilfield slurry”, International Journal of Pressure Vessels and Piping, 199 (2022), 104687 See More |

| April 2022 | Mr. Jibi. R Assistant Professor |

“Development of Boring Fixture for Lathe Machine Tool and Application of Flow Process Chart” International Journal of Engineering and Innovative Technology (IJEIT) Volume 11, Issue 10, April 2022. |

| August 2021 | Dr. Sreeram D Associate Professor |

“Effect of process parameters on machining of Al-TiC metal matrix composites using RSM” ELSEVIER SCIENCE DIRECT. |

| June 2021 | Dr. Sreeram D Associate Professor |

“Modeling and Process Parameter Optimization of Electrical Discharge Machining of Composite Materials” DESIGN ENGINEERING. |

| January 2021 | Dr. Sreeram D Associate Professor |

“Prediction of response surface roughness in electrical discharge machine for al6063 by RSM-PSO approach” KALAHARI JOURNALS. |

| September 2020 | Mr. Jibi. R Assistant Professor |

“Designing and analysis of lifting eye bolt for various geometry” International Journal of Engineering and Innovative Technology (IJEIT) Volume 10, Issue 3, September 2020. |

| July 2020 | Dr. Shahir. V K Professor |

“Review of types of biodiesels for use in internal combustion engines” International Conference on Sustainable Technology Applications for Green Engineering Solutions (STAGE) 2020. ISBN: 978-93-5406-794-5, Volume-I, Issue-I, July 2020 NSS CE Palakkad. |

| June 2020 | Dr. Shahir. V K Professor |

“Experimental investigation on performance and emission characteristics of a common rail direct injection engine using tyre pyrolytic biofuel” Journal of King Saud University – Engineering Sciences. 32 (2020) 78–84. |

| May 2020 | Mr. Jibi. R Assistant Professor |

“Designing and Modeling of Gating System and Feeder for Brass Flange Casting” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 11, May 2020. |

| May 2020 | Mr. Jibi. R Assistant Professor |

“Design Analysis and Development of Draw Die for Cylindrical Cup formation” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 11, May 2020. |

| May 2020 | Dr. Sreeram D Associate Professor |

“Surface fracture analysis of stir casted AA 6063/TiC/Gr hybrid composites under different solidification rate” ELSEVIER - SCIENCE DIRECT. |

| April 2020 | Mr. Jibi. R Assistant Professor |

“Integrating CAD/CAE Design Technology for Design and Analysis of Bending Tool” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 10, April 2020. |

| April 2020 | Mr. Jibi. R Assistant Professor |

“Application of Conceptual Design for Modeling and Analysis of Leaf Jig” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 10, April 2020. |

| April 2020 | Dr. Ajmal T. S. Associate Professor |

“Influence of green inhibitor on flow-accelerated corrosion of API X70 line pipe steel in synthetic oilfield water”, Corrosion Engineering, Science and Technology, 2020;55(6):487-496. doi:10.1080/1478422X.2020.1745355 |

| November 2019 | Dr. Ajmal T. S. Associate Professor |

“Influence of laser surface modification on flow assisted corrosion (FAC) behavior of API X70 steel in oilfield water”, Conference Proceedings, TCMCRP23, Page No. 323, The Indian Institute of Metals NMD-ATM 2019, International Symposium on Advanced Materials for Industrial and Societal Applications, 13-16 November 2019, Trivandrum |

| September 2019 | Mr. Jibi. R Assistant Professor |

“Productivity Enhancement through Design and Development of Milling Fixture” International Journal of Engineering and Innovative Technology (IJEIT) Volume 9, Issue 3, September 2019. |

| May 2019 | Dr. Ajmal T. S. Associate Professor |

“Effect of hydrodynamics on the flow accelerated corrosion (FAC) and electrochemical impedance behavior of line pipe steel for petroleum industry”, International Journal of Pressure Vessels and Piping, 174, 2019, 42–53. see more |

| March 2018 | Dr. Ajmal T. S. Associate Professor |

“Flow Accelerated Corrosion of API X70 Pipeline Steel in Oilfield Water”, Conference Proceedings, ISBN 9788193342824 (75), 5th CORSYM (International Corrosion Prevention Symposium for Research Scholars organized by NACE International), 23-24 March 2018, IIT Madras |